一、Product Introduction

The Pneumatic Insulation Ball Valve (model: Q647BJF/Q647YJF) is a specialized automated fluid control device integrating pneumatic drive and thermal insulation functions. It is mainly designed for pipeline systems transporting easily solidified, crystallized, or viscous media (such as crude oil, heavy oil, asphalt, resin, and chemical slurries) that require constant temperature maintenance. The valve adopts a jacketed insulation structure, where the interlayer can be filled with thermal insulation materials (e.g., glass wool, rock wool) or passed through heat transfer media (e.g., hot water, steam) to ensure the medium remains in a flowing state during transportation and prevent operational failures caused by temperature drop.

Driven by double-acting or single-acting (spring return) pneumatic actuators, the valve can realize rapid on-off control and can be equipped with accessories such as solenoid valves, limit switches, and positioners to achieve remote automatic control and precise position monitoring. Its valve body and internal components are available in multiple material options (carbon steel, stainless steel, alloy steel, etc.), and the sealing surface can be selected as soft sealing (PTFE, PPL) or hard sealing (hard alloy) according to working conditions, making it widely applicable to petroleum, chemical, pharmaceutical, food, and thermal power industries.

The product complies with national (GB), American (ANSI), and Japanese (JIS) standards in structural design, with customizable insulation layer thickness, flange size, and structural length to meet the special requirements of different industrial pipeline systems.

二、Product Features

-

Efficient Thermal Insulation Structure: The valve body is designed with a double-layer jacket, and the insulation interlayer has good thermal insulation performance. It can effectively reduce heat loss of the medium, maintain stable medium temperature, and avoid energy waste and pipeline blockage caused by medium solidification.

-

Reliable Pneumatic Drive: Equipped with high-performance pneumatic actuators, it has fast response speed (opening/closing time ≤ 5 seconds for small and medium specifications) and stable operation. The single-acting type has a spring return function, which can automatically reset to the safe position (open or closed) when the air source is interrupted, ensuring operational safety.

-

Strong Adaptability to Working Conditions: Multiple material and sealing combinations are available. The valve body made of alloy steel can withstand high temperatures up to 350℃, and the hard-sealed structure has excellent wear resistance and corrosion resistance, which can adapt to harsh working conditions such as high temperature, high pressure, and corrosive media.

-

Comprehensive Safety Protection: Equipped with anti-static devices (connecting the valve stem and valve body to prevent static accumulation) and fire protection structures (the sealing surface can maintain basic sealing after fire), effectively reducing potential safety hazards in industrial operations.

-

Easy Installation and Maintenance: Adopts standard flange connection, which is convenient for on-site installation and disassembly. The internal structure is compact, and the wearing parts (valve seat, sealing ring) are easy to replace, reducing maintenance costs and downtime.

-

Intelligent Control Compatibility: It can be seamlessly matched with intelligent accessories such as electro-pneumatic positioners and intelligent controllers to realize proportional adjustment of the medium flow, meeting the needs of precise process control.

三、Technical Data

1. Performance Specifications

|

Item

|

Parameter

|

|---|---|

|

Model

|

Q647BJF (soft seal), Q647YJF (hard seal)

|

|

Nominal Diameter

|

DN15 – DN300 mm (1/2″ – 12″)

|

|

Pressure Rating

|

PN1.6 – PN6.4 MPa; Class 150 – Class 600 LB; JIS 10K – 20K

|

|

Insulation Structure

|

Jacketed type (fillable with insulation materials or circulating heat transfer medium)

|

|

Working Temperature

|

-40℃ – 350℃ (depends on insulation material and valve body material)

|

|

Valve Body Material

|

Carbon steel (WCB), stainless steel (CF8, CF8M, CF3, CF3M), alloy steel (WC6, WC9)

|

|

Sealing Material

|

Soft seal: PTFE, PPL; Hard seal: Stellite alloy, WC hard alloy

|

|

Actuator Type

|

Double-acting pneumatic actuator, Single-acting pneumatic actuator (spring return)

|

|

Control Mode

|

On-off control, Proportional adjustment (with positioner)

|

|

Applicable Medium

|

Crude oil, heavy oil, asphalt, resin, chemical slurry, viscous liquid, etc. (needing constant temperature insulation)

|

|

Optional Accessories

|

Solenoid valve, limit switch, electro-pneumatic positioner, air source treatment triplet, manual mechanism

|

2. Executive Standards

|

Item

|

GB Standard

|

ANSI Standard

|

JIS Standard

|

|---|---|---|---|

|

Design Basis

|

GB/T 12237

|

ANSI B16.34

|

JIS B2003

|

|

Flange Connection

|

GB/T 9113, JB/T 79

|

ANSI B16.5

|

JIS B2220

|

|

Structural Length

|

GB/T 12221

|

ANSI B16.10

|

JIS B2002

|

|

Testing & Inspection

|

GB/T 13927, JB/T 7902

|

API 598

|

JIS B2005

|

3. Main Parts & Materials List

|

Serial No.

|

Part Name

|

Carbon Steel Series (C)

|

Stainless Steel Series (P)

|

Alloy Steel Series (R)

|

|---|---|---|---|---|

|

1

|

Valve Body (with jacket)

|

WCB

|

CF8/CF8M

|

WC6/WC9

|

|

2

|

Ball

|

1Cr13

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

3

|

Valve Seat

|

PTFE/Stellite alloy

|

PPL/Stellite alloy

|

PPL/WC hard alloy

|

|

4

|

Valve Stem

|

2Cr13

|

1Cr18Ni9Ti

|

1Cr18Ni12Mo2Ti

|

|

5

|

Insulation Jacket

|

Q235A

|

304

|

304

|

|

6

|

Sealing Ring

|

PTFE/fluororubber

|

PTFE/fluororubber

|

PPL/fluororubber

|

|

7

|

Bolt/Nut

|

35#/45#

|

1Cr18Ni9Ti

|

25Cr2MoVA

|

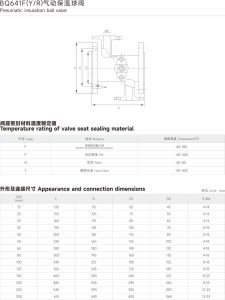

四.The main shape and connection size