一、Product Introduction

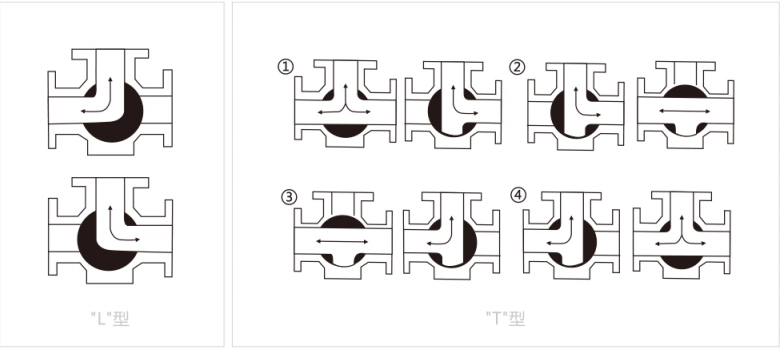

The PTFE-lined three-way ball valve is a corrosion-resistant flow control device designed for complex fluid diversion/confluence scenarios (e.g., chemical, pharmaceutical, environmental protection industries). It combines a stainless steel valve body with a PTFE (or F46/PFA) lining, achieving both mechanical strength and chemical inertness. Its 3-way flow path (L-type/T-type) enables flexible switching between two-in-one-out or three-directional flow, effectively isolating corrosive media from the metal body to ensure long-term stable operation in harsh environments (e.g., strong acids, alkalis, organic solvents).

二、Product Features

-

Superior Corrosion ResistanceThe PTFE/F46/PFA lining resists almost all corrosive media (except molten alkali metals and elemental fluorine), suitable for extreme chemical environments.

-

Flexible Flow ControlSupports L-type (directional switching) and T-type (diversion/confluence) flow paths, adapting to diverse pipeline process requirements.

-

Zero Leakage SealingFloating ball structure + PTFE sealing seats realize bidirectional zero leakage, even under high-pressure conditions.

-

Lightweight & DurableStainless steel body reduces weight; the molded lining ensures uniform thickness and long service life, lowering maintenance costs.

-

Multiple Actuation OptionsCompatible with manual, pneumatic, or electric actuators (90° quick opening/closing), meeting automated control needs.

三、Technical Data

| Parameter | Specification |

|---|---|

| Nominal Diameter | DN15–DN300 (1/2″–12″) |

| Pressure Rating | PN1.0–PN2.5 MPa (Class150–Class300) |

| Operating Temperature | -50°C to 180°C (depends on lining material) |

| Connection Type | Flange (GB/T9113, HG/T20592) |

| Lining Material | PTFE, F46, PFA |

| Applicable Media | Strong acids, alkalis, organic solvents, etc. |

| Design Standard | GB/T12237, API 608 |

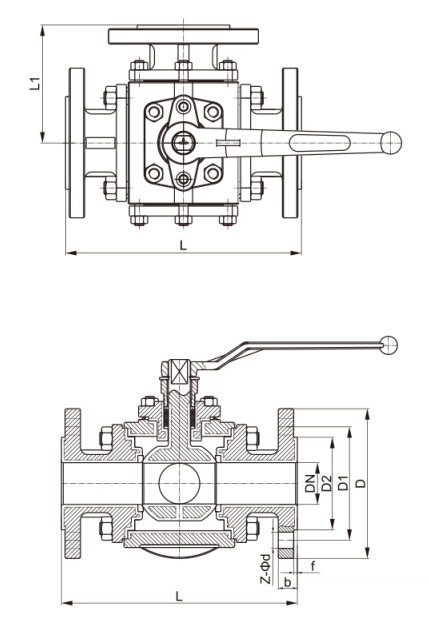

四.The main shape and connection size

Main connection dimensions

| Nominal diameter | Standard value (unit: mm) | |||||||

| DN (mm) |

L | L1 | D | D1 | D2 | f | b | Z-Φd |

| PN1.0MPa | ||||||||

| 25 | 240 | 120 | 115 | 85 | 68 | 3.5 | 18 | 4-Φ14 |

| 32 | 240 | 120 | 140 | 100 | 78 | 3.5 | 18 | 4-Φ18 |

| 40 | 260 | 130 | 150 | 110 | 88 | 3.5 | 18 | 4-Φ18 |

| 50 | 260 | 130 | 165 | 125 | 102 | 4 | 18 | 4-Φ18 |

| 65 | 320 | 160 | 185 | 145 | 122 | 4 | 18 | 8-Φ18 |

| 80 | 320 | 160 | 200 | 160 | 138 | 4 | 20 | 8-Φ18 |

| 100 | 370 | 185 | 220 | 180 | 158 | 4.5 | 20 | 8-Φ18 |

| 125 | 510 | 255 | 250 | 210 | 188 | 4.5 | 22 | 8-Φ18 |

| 150 | 510 | 255 | 285 | 240 | 212 | 4.5 | 22 | 8-Φ22 |

| 200 | 580 | 290 | 340 | 295 | 268 | 5 | 24 | 8-Φ22 |

| 250 | 670 | 335 | 395 | 350 | 320 | 5 | 26 | 12-Φ22 |

| 300 | 760 | 380 | 445 | 400 | 370 | 5 | 26 | 12-Φ22 |

Main connection dimensions

| Nominal diameter | Standard value (unit: mm) | |||||||

| DN (mm) |

L | L1 | D | D1 | D2 | f | b | Z-Φd |

| PN1.6MPa | ||||||||

| 25 | 240 | 120 | 115 | 85 | 68 | 3.5 | 18 | 4-Φ14 |

| 32 | 240 | 120 | 140 | 100 | 78 | 3.5 | 18 | 4-Φ18 |

| 40 | 260 | 130 | 150 | 110 | 88 | 3.5 | 18 | 4-Φ18 |

| 50 | 260 | 130 | 165 | 125 | 102 | 4 | 18 | 4-Φ18 |

| 65 | 320 | 160 | 185 | 145 | 122 | 4 | 18 | 8-Φ18 |

| 80 | 320 | 160 | 200 | 160 | 138 | 4 | 20 | 8-Φ18 |

| 100 | 370 | 185 | 220 | 180 | 158 | 4.5 | 20 | 8-Φ18 |

| 125 | 510 | 255 | 250 | 210 | 188 | 4.5 | 22 | 8-Φ18 |

| 150 | 510 | 255 | 285 | 240 | 212 | 4.5 | 22 | 8-Φ22 |

| 200 | 580 | 290 | 340 | 295 | 268 | 5 | 24 | 12-Φ22 |

| 250 | 670 | 335 | 405 | 355 | 320 | 5 | 26 | 12-Φ26 |

| 300 | 760 | 380 | 460 | 410 | 378 | 5 | 28 | 12-Φ26 |