I. Product Introduction

Flange connection ball valves (two-piece and three-piece types) are critical control components widely applied in various industrial pipeline systems, designed for on-off control and throttling adjustment of media. The two-piece and three-piece structural designs not only ensure the overall tightness and structural stability of the valve but also provide significant convenience for installation, maintenance, and disassembly. Specifically, the two-piece flange ball valve features a compact structure, integrating the valve body and one end of the connection part, which is suitable for occasions with relatively simple working conditions and high requirements for space saving. The three-piece flange ball valve is composed of a middle valve body and two end covers; its detachable structure allows for easy removal of the middle valve body for maintenance or parts replacement without disassembling the entire pipeline, making it ideal for complex working conditions and frequent maintenance needs.

This series of ball valves is mainly made of carbon steel for key components, complemented by high-performance lining and sealing materials. It exhibits excellent corrosion resistance, pressure-bearing capacity, and wear resistance, and can be widely used in petroleum, chemical, metallurgy, water treatment, power generation, and other industries. It is suitable for various media such as water, oil, gas, and some corrosive fluids, effectively ensuring the safe and stable operation of the pipeline system.

II. Product Features

-

Superior Structural Design: The two-piece and three-piece structures are reasonably designed. The two-piece type has a compact size, small occupied space, and low flow resistance, ensuring efficient media circulation. The three-piece type enables separate disassembly and maintenance of the valve body, greatly reducing maintenance costs and downtime, and improving the operability of the equipment.

-

Excellent Sealing Performance: Adopting high-quality lining/seat materials such as PTFE (F4), PCTFE (F3), FEP (F46), and PO, combined with advanced sealing technology, the valve achieves reliable sealing under both positive and negative pressure conditions, effectively preventing media leakage and ensuring the safety of the production environment.

-

Strong Adaptability: With a nominal pressure range of PN0.6~1.6MPa and a nominal diameter range of DN15~350mm, it can meet the needs of different pipeline specifications and working pressure requirements. The carbon steel material used for the main components has good mechanical properties and toughness, adapting to various harsh working environments.

-

Easy Operation and Maintenance: The valve is available in multiple operation modes such as manual, pneumatic, worm gear, and electric, to meet the needs of different automation levels. The key components have standardized dimensions and interchangeability, facilitating quick replacement of wearing parts. Meanwhile, the smooth surface of the sphere reduces friction loss and extends the service life of the valve.

-

Compliance with Strict Standards: The design, manufacturing, structure length, flange size, pressure test, marking, and filling all comply with national and industry standards such as GB/T 12237, HG/T 3704, HG/T 20592, and GB/T 13927, ensuring the product’s quality and compatibility.

III. Technical Data (Carbon Steel)

1. Basic Parameters

Nominal Pressure: PN0.6~1.6 (MPa)

Nominal Diameter: DN15~350 (mm)

Valve Type: Two-piece/Three-piece flange connection ball valve (floating ball type)

2. Floating Ball Valve Torque (Carbon Steel, Pressure: 1.6MPa)

|

Caliber (DN)

|

Stresses (MPa)

|

Torques (N·m)

|

|---|---|---|

|

15

|

1.6

|

14

|

|

20

|

1.6

|

14

|

|

25

|

1.6

|

14

|

|

32

|

1.6

|

22

|

|

40

|

1.6

|

23

|

|

50

|

1.6

|

34

|

|

65

|

1.6

|

69

|

|

80

|

1.6

|

89

|

|

100

|

1.6

|

171

|

|

125

|

1.6

|

318

|

|

150

|

1.6

|

432

|

|

200

|

1.6

|

665

|

|

250

|

1.6

|

1245

|

|

300

|

1.6

|

2495

|

3. Implementation Standards

|

Item

|

Standard Number

|

|---|---|

|

Design and Manufacturing

|

GB/T 12237

|

|

Structure Length

|

HG/T 3704

|

|

Flange Size

|

HG/T 20592

|

|

Pressure Test

|

GB/T 13927

|

|

Symbolize

|

GB/T 12220

|

|

Fill

|

JB/T 7928

|

4. Basic Model (Fully Lined, Carbon Steel Base Material)

|

Operation Mode

|

Model

|

Lining Feature

|

|---|---|---|

|

Manually

|

Q41F4, Q41PFA, Q41F46

|

Full Lining

|

|

Pneumatic

|

Q641F4, Q641PFA, Q641F46

|

Full Lining

|

|

Worm-gear Rotation

|

Q341F4, Q341PFA, Q341F46

|

Full Lining

|

|

Electricity

|

Q941F4, Q941PFA, Q941F46

|

Full Lining

|

5. Main Parts and Components Material Table (Carbon Steel)

|

Serial Number

|

Part Name

|

Carbon Steel Material

|

Note

|

|---|---|---|---|

|

1

|

Valve Body, Valve Cover

|

WCB

|

–

|

|

2

|

Sphere

|

WCB

|

–

|

|

3

|

Lining/Seat

|

PT, FE(F₄), PCTFE(F3), FEP(F46), PO

|

Lining materials for corrosion resistance

|

|

4

|

Packing Gland

|

WCB

|

–

|

|

5

|

Packing Material

|

PTFE(F4) Polytetrafluoroethylene

|

High-temperature and corrosion-resistant

|

|

6

|

Stem (Note: Corrected from “Video Game Controller”)

|

WCC

|

Transmits operation torque

|

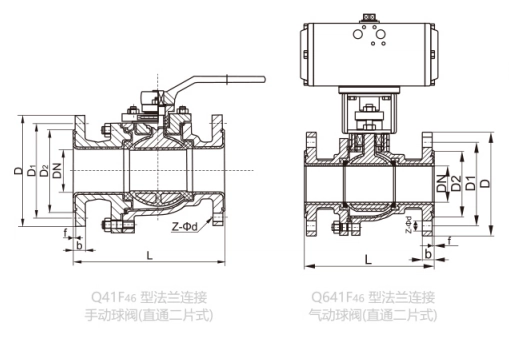

Ⅳ.The main shape and connection size

| ominal diameter | Standard value (unit: mm) | reference point | ||||||

| L | D | D1 | D2 | f | b | Z-Φd | W(kg) | |

| PN1.0MPa | ||||||||

| 15 | 140 | 95 | 65 | 45 | 3 | 16 | 4-Φ14 | 2.5 |

| 20 | 140 | 105 | 75 | 58 | 3 | 18 | 4-Φ14 | 3 |

| 25 | 150 | 115 | 85 | 68 | 3.5 | 18 | 4-Φ14 | 4.5 |

| 32 | 165 | 140 | 100 | 78 | 3.5 | 18 | 4-Φ18 | 5.7 |

| 40 | 180 | 150 | 110 | 88 | 3.5 | 18 | 4-Φ18 | 7 |

| 50 | 200 | 165 | 125 | 102 | 4 | 18 | 4-Φ18 | 9.5 |

| 65 | 220 | 185 | 145 | 122 | 4 | 18 | 8-Φ18 | 15 |

| 80 | 250 | 200 | 160 | 138 | 4 | 20 | 8-Φ18 | 19 |

| 100 | 280 | 220 | 180 | 158 | 4.5 | 20 | 8-Φ18 | 33 |

| 125 | 320 | 250 | 210 | 188 | 4.5 | 22 | 8-Φ18 | 58 |

| 150 | 360 | 285 | 240 | 212 | 4.5 | 22 | 8-Φ22 | 93 |

| 200 | 400 | 340 | 295 | 268 | 5 | 24 | 8-Φ22 | 155 |

| 250 | 450 | 395 | 350 | 320 | 5 | 26 | 12-Φ22 | 210 |

| 300 | 610 | 445 | 400 | 370 | 5 | 26 | 12-Φ22 | 330 |

| 350 | 686 | 505 | 460 | 430 | 5 | 26 | 16-Φ22 | 440 |

| 400 | 762 | 565 | 515 | 482 | 5 | 26 | 16-Φ26 | 550 |

| PN1.6MPa | ||||||||

| 15 | 140 | 95 | 65 | 45 | 3 | 16 | 4-Φ14 | 2.5 |

| 20 | 140 | 105 | 75 | 58 | 3 | 18 | 4-Φ14 | 3 |

| 25 | 150 | 115 | 85 | 68 | 3.5 | 18 | 4-Φ14 | 4.5 |

| 32 | 165 | 140 | 100 | 78 | 3.5 | 18 | 4-Φ18 | 5.7 |

| 40 | 180 | 150 | 110 | 88 | 3.5 | 18 | 4-Φ18 | 7 |

| 50 | 200 | 165 | 125 | 102 | 4 | 18 | 4-Φ18 | 9.5 |

| 65 | 220 | 185 | 145 | 122 | 4 | 18 | 8-Φ18 | 15 |

| 80 | 250 | 200 | 160 | 138 | 4 | 20 | 8-Φ18 | 19 |

| 100 | 280 | 220 | 180 | 158 | 4.5 | 20 | 8-Φ18 | 33 |

| 125 | 320 | 250 | 210 | 188 | 4.5 | 22 | 8-Φ18 | 58 |

| 150 | 360 | 285 | 240 | 212 | 4.5 | 22 | 8-Φ22 | 93 |

| 200 | 400 | 340 | 295 | 268 | 5 | 24 | 12-Φ22 | 155 |

| 250 | 450 | 405 | 355 | 320 | 5 | 26 | 12-Φ26 | 210 |

| 300 | 610 | 460 | 410 | 378 | 5 | 28 | 12-Φ26 | 350 |

| 350 | 686 | 520 | 470 | 428 | 5 | 30 | 16-Φ26 | 460 |

| 400 | 762 | 580 | 525 | 490 | 5 | 32 | 16-Φ30 | 550 |

| PN2.5MPa | ||||||||

| 15 | 140 | 95 | 65 | 45 | 3 | 16 | 4-Φ14 | 2.5 |

| 20 | 140 | 105 | 75 | 58 | 3 | 18 | 4-Φ14 | 3 |

| 25 | 150 | 115 | 85 | 68 | 3.5 | 18 | 4-Φ14 | 4.5 |

| 32 | 165 | 140 | 100 | 78 | 3.5 | 18 | 4-Φ18 | 5.7 |

| 40 | 180 | 150 | 110 | 88 | 3.5 | 18 | 4-Φ18 | 7 |

| 50 | 200 | 165 | 125 | 102 | 4 | 20 | 4-Φ18 | 9.5 |

| 65 | 220 | 185 | 145 | 122 | 4 | 22 | 8-Φ18 | 15 |

| 80 | 250 | 200 | 160 | 138 | 4 | 24 | 8-Φ18 | 19 |

| 100 | 280 | 235 | 190 | 160 | 4.5 | 24 | 8-Φ22 | 33 |

| 125 | 320 | 270 | 220 | 188 | 4.5 | 26 | 8-Φ26 | 58 |

| 150 | 360 | 300 | 250 | 218 | 4.5 | 28 | 8-Φ26 | 93 |

| 200 | 400 | 360 | 310 | 278 | 5 | 30 | 12-Φ26 | 155 |

| 250 | 450 | 425 | 370 | 335 | 5 | 32 | 12-Φ30 | 210 |

| 300 | 610 | 485 | 430 | 395 | 5 | 34 | 16-Φ30 | 230 |

| 350 | 686 | 555 | 490 | 450 | 5 | 38 | 16-Φ33 | 250 |