一.Product Introduction

The Pneumatic V port Ball Control Valve is primarily designed for flow control, and it can also be used for shut-off

operation. The notched port on the segment ball contributes to strong shear stress to cut through media with fibers

and particles. Consequently, this Segment Ball Valve is a good general control valve (equal percentage flow character)

for most pulp and paper process applications, or similar flow contains fibers and particles.

二.Product Features

1.Integral body design boosts rigidity against fluctuating pipe loads, eliminates two-piece body leak paths, and offers wafer/flange connections.

2.Special V-notch ball delivers strong cutting stress and tight sealing; optional hard chromium/nitriding/HCOF treatments enhance hardness, wear/corrosion/fatigue resistance and high-temperature performance.

3.Precision-ground notched ball surface reduces operating torque, ensuring tight seal (ideal for metal-seated segment valves).

4.For Class 150 valves, integrally cast seat retainer prevents residue accumulation; specialized spring cuts torque while ensuring sealing force, with pressure-energized seat enabling excellent sealing at ultra-low differential pressures.

5.Finely ground stem fits actuator perfectly, avoiding wobble and potential segment valve failures.

三.Technical data

| VQ647H、VQ677H Pneumatic V-Type Adjusting Ball Valve Specifications | |

| Nominal pressure: | 1.6 /2.5/4.0 Mpa |

| Strength test: | 2.4/3.75/6.0Mpa |

| Seal test: | 1.76/2.75/4.4 Mpa |

| Gas seal test: | 0.6Mpa |

| Valve body material: | WCB(C) / CF8 (P) / CF3 (PL) / CF8M (R) / CF3M (RL) |

| Suitable medium: | Water/oil/steam ect. |

| Suitable temperature: | -28℃~+550℃ |

| NO. | Part name | Material |

| 1 | Body | WCB/CF8 |

| 2 | Bonnet | WCB/CF8 |

| 3 | Sealing | 2Cr13 |

| 4 | Ball | 2Cr13 |

| 5 | Valve Seat | 2Cr13 |

| 6 | gasket | 304/316 |

| 7 | Nut | 304/316 |

| 8 | Screw | 304/316 |

| 9 | Bolt | 304/316 |

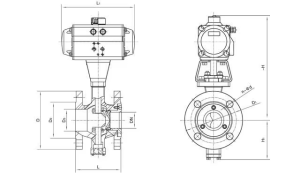

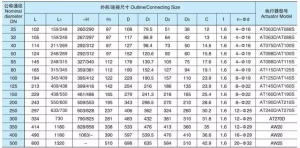

四.The main shape and connection size