If you work with pneumatic systems, you know that the right valve can make all the difference in efficiency and reliability. Today, we’re taking a closer look at one of the most straightforward yet essential components in the field: the push-pull pneumatic valve.

What Is a Push-Pull Pneumatic Valve?

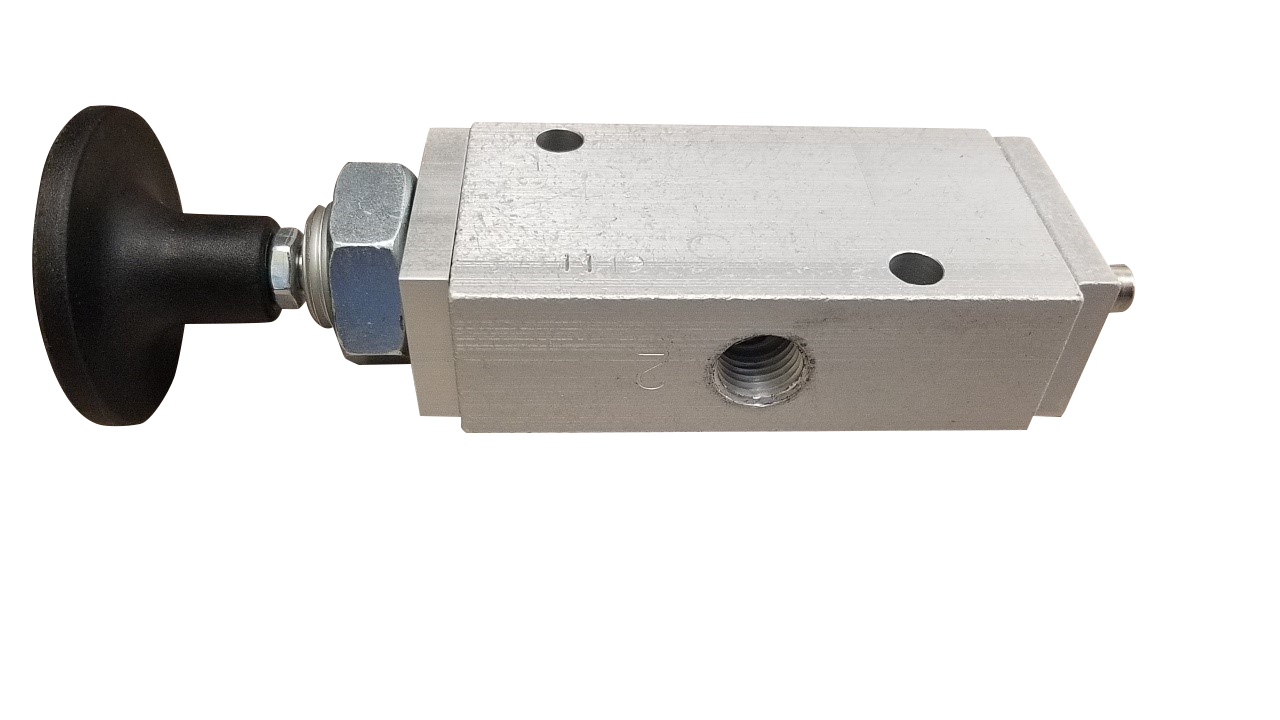

At its core, a push-pull pneumatic valve is a manually operated directional control valve that uses a simple push or pull action to control the flow of compressed air. The valve in the image is a classic example: its rugged aluminum body and large, ergonomic black knob make it easy to operate even with gloves on, which is a huge plus in industrial environments.

These valves typically use a 3/2 (3-port, 2-position) or 5/2 (5-port, 2-position) design. When you pull the knob, you engage one air path; when you push it back, you reset the valve to its default state, redirecting or blocking airflow as needed. No electricity, no complex electronics—just pure mechanical control.

Why Choose a Push-Pull Valve?

1. Simplicity & Durability

With no solenoids or fragile components, push-pull valves are built to last. The hard-anodized aluminum resists corrosion and impacts, while the sealed spool mechanism ensures smooth operation even in dusty, dirty conditions. For applications where reliability is non-negotiable, this valve is a workhorse.

2. Instant, Precise Control

In scenarios where you need immediate, tactile feedback—like emergency stops, manual machine actuation, or small-scale assembly tasks—nothing beats the direct response of a push-pull valve. There’s no lag time, and you always know exactly what state the valve is in at a glance.

3. Cost-Effective & Low-Maintenance

Compared to solenoid valves, push-pull models are budget-friendly and require almost no upkeep. There are no coils to burn out or sensors to calibrate—just occasional lubrication to keep the spool moving freely. This makes them ideal for small businesses, hobbyists, or any setup where keeping costs low is a priority.

Common Applications

- Machine Tools: Controlling clamping cylinders or tool changers.

- Packaging Equipment: Actuating grippers and conveyor stops.

- DIY & Hobby Projects: Powering pneumatic actuators in home-built machines.

- Emergency Stops: Providing a manual override for safety-critical systems.

Final Thoughts

In a world of increasingly complex automation, the push-pull pneumatic valve remains a testament to the power of simplicity. It’s not the flashiest component in your pneumatic toolkit, but it’s one you’ll be glad to have when you need a reliable, no-fuss solution.

Whether you’re a seasoned maintenance technician or a weekend tinkerer, this valve proves that sometimes the best tools are the ones that just work—every time.