A wafer check valve is a compact, lightweight non-return valve designed to let fluids flow in one direction while automatically blocking reverse flow. Installed neatly between pipe flanges, it saves space, reduces weight, and protects pumps, pipelines, and equipment from damage caused by backflow or water hammer. Thanks to their efficiency, reliability, and versatility across industries like water treatment, HVAC, oil and gas, and chemical processing, wafer check valves have become a go-to solution for ensuring safe and uninterrupted fluid control.

Table of Contents

What Is a Wafer Check Valve?

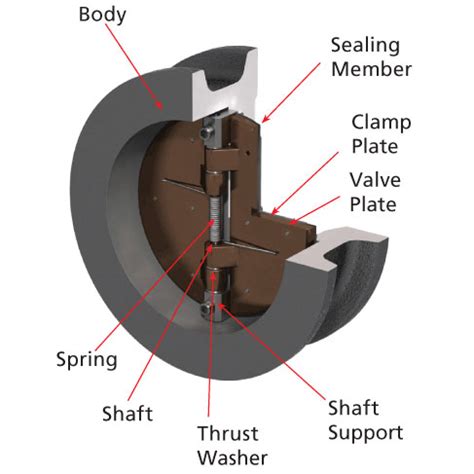

A wafer check valve is a type of compact, in-line, one-way (non-return) valve designed to allow fluid to flow in only one direction while automatically preventing reverse flow. Installed snugly between two flanges, it’s also known as a reflux valve, clack valve, or non-return valve.

The heart of the wafer check valve is a hinge-mounted or spring-assisted disc (or pair of discs), which opens when upstream pressure exceeds downstream pressure, and snaps shut when flow reverses, thereby protecting pipes and equipment from backflow.

In short, wafer check valves deliver automatic, reliable one-directional fluid control—all in a space-saving, lightweight format ideal for constrained piping systems.

How Does a Wafer Check Valve Work?

A wafer check valve operates automatically—no external power or manual input required—using a simple interplay of forward pressure, spring force (in some variants), and gravity to control flow direction.

Forward Flow (Open State)

When fluid pressure from the upstream side exceeds the downstream pressure (and spring tension, if present), the valve’s disc—or dual plates—are pushed open, allowing fluid to pass through with minimal resistance and energy loss.

Reverse Flow or Flow Cessation (Closed State)

Once flow stops or reverses, the disc—or discs—quickly return to a closed position. This closure is driven by the backflow pressure and, in spring-assisted designs, additional spring force. The result: reliable prevention of reverse flow and protection against potentially damaging events like water hammer.

Key Features & Advantages

Compact Design

Wafer check valves are engineered with a wafer-thin body that fits snugly between pipe flanges, significantly reducing the valve’s profile compared to bulkier styles. This sleek design ensures minimal space usage and adds virtually no bulk to the piping system.

Space & Weight Benefits

-

Space-saving: Their slim configuration makes wafer check valves perfect for tight installations—whether in small-bore piping, compact skids, or retrofit systems with limited clearance.

-

Lightweight: These valves are lighter than conventional swing or lift check valves, easing handling, reducing stress on pipe supports, and simplifying installation logistics.

Cost-Effectiveness

Wafer check valves generally cost less to manufacture and install. Their simplified design uses fewer materials and lacks complex hardware, which translates to lower initial costs. Plus, quick installation between standard flanges reduces labor time and system downtime.

Versatility in Applications

These valves suit a wide range of industries and purposes:

-

Flexible sizing & specs: Available in many sizes, pressure classes, and configurations to match diverse systems.

-

Wide-ranging compatibility: Materials and seating options cater to fluids, steam, slurries, and corrosive media.

-

Broad deployment: Ideal for sectors like HVAC, petrochemical, water treatment, power generation, and more, especially where space, weight, and efficiency matter.

Types of Wafer Check Valves

Single Plate Wafer Check Valve

Single plate wafer check valves—also known as single-disc or swing-type wafer valves—feature a single hinged disk mounted between flanges. When fluid flows forward, the disc swings open; when flow reverses, gravity or back pressure causes it to swing shut and block backflow.

Advantages:

-

Simple, reliable, and easy to maintain

-

Cost-effective and lighter than traditional check valves

-

Ideal for low-flow or low-pressure systems where backflow risk is modest

Considerations:

-

Slower closing and less effective sealing may allow leakage in high-speed or high-pressure flows

Dual Plate Wafer Check Valve

Dual plate (or split-disc) wafer check valves use two semicircular plates hinged at the center. These plates open under forward flow and spring back to seal tightly when flow reverses.

Advantages:

-

Compact, lightweight design that minimizes pressure drop

-

Fast, non-slam closure (thanks to spring assistance), reducing water hammer and operational stress

-

Better sealing performance and more durability in high-flow, high-pressure environments

-

Often designed without body-penetrating pins (retainer-less), enhancing safety in sensitive applications

Considerations:

-

More complex and generally costlier to manufacture

-

Potential for noise or vibration under certain conditions

Single Plate vs. Dual Plate: Quick Comparison

| Feature | Single Plate Wafer Check Valve | Dual Plate Wafer Check Valve |

|---|---|---|

| Closure Mechanism | Single hinged disc, typically gravity or pressure-driven | Two spring-loaded plates closing rapidly under reverse flow |

| Pressure Drop | Higher, due to single disc blocking more flow area | Lower, more streamlined design |

| Response Speed | Relatively slower, may allow slamming | Fast, non-slam action reduces water hammer risk |

| Suitability | Low-flow, low-pressure systems; cost-sensitive applications | High-flow, high-pressure systems; critical backflow protection |

| Complexity & Cost | Simple and economical | More complex and higher upfront cost |

Comparison: Wafer vs. Other Check Valves

Flanged vs. Wafer Check Valves

Wafer Check Valves

-

Designed to be sandwiched between two flange faces, wafer check valves feature a compact, lightweight profile that conserves space and minimizes weight in piping systems. Installation is streamlined, requiring only alignment and gasket insertion between flanges.

-

The short disc travel, often aided by spring mechanisms, enables quick closure, effectively reducing water hammer and lowering fluid resistance.

-

These valves are especially effective in tight-space applications where rapid response and minimal footprint are priorities.

Flanged Check Valves

-

These valves are bolted directly to pipe flanges, resulting in a larger and heavier body with a sturdier connection.

-

Because their discs typically traverse a longer path, closing times are slower, which can lead to higher water hammer pressure.

-

Such valves are best suited for high-pressure environments or systems demanding robust, reliable connections—common in petrochemical, power generation, and industrial settings.

Quick Comparison: Flanged vs. Wafer

| Feature | Wafer Check Valve | Flanged Check Valve |

|---|---|---|

| Profile | Slim, lightweight | Bulky, heavy-duty |

| Installation | Sandwich-style, gasket-based | Bolted connection |

| Response Speed | Fast closing, less water hammer | Slower closing, higher water hammer |

| Ideal Use Cases | Space-constrained, quick-response systems | High-pressure, heavy-duty systems |

Swing vs. Wafer Check Valves

Wafer Check Valves

-

Their wafer-thin design is tailored for tight piping layouts.

-

They exhibit excellent anti-clogging characteristics and a low-pressure drop, making them ideal for fluid systems with suspended particles or debris.

-

Often lighter, more efficient, and more cost-effective than swing check valves.

Swing Check Valves

-

Feature a disc suspended from a hinge pin, encased within a molded body that provides space for the disc to open fully—supporting full flow capacity.

-

Offer low turbulence and pressure drop, with readily replaceable seat rings and good sealing performance.

-

Not recommended for pulsating flow, as the repeated motion can damage sealing surfaces over time.

Quick Comparison: Swing vs. Wafer

| Feature | Wafer Check Valve | Swing Check Valve |

|---|---|---|

| Design | Slim, space-saving, between flanges | Molded body with ample disc swing space |

| Flow Capacity | Moderate; some restriction | Full flow capability |

| Ideal Use Cases | Compact systems; fluids with debris | Systems demanding full flow (water/gas) |

| Durability | Efficient and cost-effective | Low turbulence, but sensitive to pulsation wear |

Where Wafer Check Valves Are Commonly Used

-

Water Treatment & Purification

Widely deployed in water intakes, purification systems, desalination plants, membrane filtration, and aquariums to ensure unidirectional flow and prevent contamination or backflow. -

Pump Discharge Lines & HVAC Circuits

Installed at pump outlets to avoid reverse flow when the pump shuts off, protecting pump components. Frequently used in heating, cooling, and circulation systems in HVAC applications. -

Chemical, Petrochemical & Industrial Processes

Common in pipelines carrying corrosive or reactive fluids—such as acids, bases, and bleach—ensuring reliable one-way flow and guarding against backflow that might lead to contamination or equipment damage. -

Marine & Offshore Systems

Favored in seawater desalination and offshore platform applications due to their corrosion-resistant materials and compact type design, suitable for harsh marine environments. -

Power Generation & High-Rise Water Systems

Utilized in cooling water lines of power plants (thermal and nuclear) and in vertical water distribution systems within tall buildings to prevent pressure fluctuations and ensure stable, one-directional flow. -

Food, Pharmaceutical & Sanitary Applications

Employed where hygiene is critical—such as food processing and pharmaceutical systems—thanks to their ability to be made from materials like stainless steel with high-polishing, ensuring contamination-free flow. -

Boiler Feed Lines, Vacuum Breakers & Steam Applications

Used in boiler feedwater systems, hot water circuits, vacuum breaker assemblies, steam traps, blowdown, and flash vessels—especially in refineries, HVAC systems, and gas/liquid separation setups. -

Additional Applications (Tanks, Mining & Swimming Pools)

Found at tank inlets/outlets, for preventing backflow into pumps, one-way mixing, mitigating water hammer, and pressure balancing. Also used in mining, landfills, bleach plants, aquariums, chemical plants, and swimming pools.

Selection Guide

1. Define Application Needs & System Conditions

Your starting point: clearly understand the environment where the valve will be used. Consider critical factors such as:

-

Fluid type—Is it water, oil, gas, slurry, or corrosive chemicals?

-

Operating conditions—What are the system’s maximum pressure and temperature?

-

Flow dynamics—Are rapid flow reversals or water hammer likely?

-

Space constraints—Is the piping compact or expansive?

These parameters help you narrow down suitable materials and configurations.

2. Match Material to Fluid and Environment

Your valve’s body and disc materials must resist corrosion and wear from the fluid and environmental conditions. Common material options include:

-

Stainless steel—ideal for corrosive or hygienic media.

-

Carbon steel or cast iron—good for standard service with less corrosive fluids.

-

PVC or other polymers—fit for non-corrosive, lower-pressure systems.

Avoid mismatches—like using brass or mild steel with aggressive chemicals—as this can lead to premature failure.

3. Determine Proper Size & Pressure Rating

Valve sizing must align with both the pipe diameter and the desired flow rate:

-

Selecting the correct valve size prevents excess pressure drop and turbulence.

-

Ensure the pressure and temperature ratings exceed system demands to avoid failure.

4. Consider Valve Dynamics & Performance Needs

Different wafer check valve designs address various operational challenges:

-

Spring-assisted or dual-plate wafer valves provide rapid, non-slam closure, protecting against water hammer in high-cycle systems.

-

Basic single-plate models may suffice for slow, steady flows and simpler setups.

5. Check Installation Compatibility

Ensure the valve aligns with your piping standards:

-

Does it conform to your flange standards (e.g., ANSI, DIN, JIS)?

-

Is its compact wafer-style suitable for horizontal, vertical, or inclined installation?

These details impact both ease of installation and long-term reliability.

6. Plan for Maintenance & Total Cost of Ownership

Balancing upfront and long-term costs is key:

-

Wafer check valves are less expensive initially and easier to handle due to lighter weight.

-

However, their compact design may complicate access during servicing.

-

Factor in maintenance frequency—frequent inspections in harsh environments could tilt the balance of value toward designs that offer easier servicing.

Common Issues & Troubleshooting

Failure Modes (Typical Issues with Wafer Check Valves)

Debris Jamming / Contamination

Foreign particles can lodge between sealing surfaces or inside the valve, causing it to stick open or closed—or even leak unexpectedly. This disruption undermines its primary function of preventing backflow.

Reverse Flow (Backflow)

When the valve fails to seal properly—due to wear or contamination—fluid may flow backward, potentially damaging pumps and leading to operational inefficiencies.

Water Hammer and Noise

Sudden closure under high flow can cause a pressure surge (water hammer), leading to loud noises, vibrations, and stress on both valve and piping systems.

Chatter (Repeated Rapid Opening/Closing)

If the valve is oversized, or cracking pressure doesn’t match system conditions, it may flutter (“chatter”), accelerating wear on sealing surfaces and internal components.

Insufficient Flow / Silt Accumulation

When flow doesn’t fully open the valve, particles can settle at the seat, causing partial closure or malfunction due to uneven movement.

Mechanical Wear or Misalignment

Valve discs may fail to lift smoothly, springs or hinges may stick, or components may wear due to improper clearance, pressure fluctuations, or poor installation.

Solutions for Common Problems

| Issue | Solution |

|---|---|

| Debris & Contamination | Install filters upstream, regularly flush the system, and perform scheduled cleaning to prevent blockages. |

| Backflow / Reverse Flow | Monitor for leakage; replace worn seats, recheck installation alignment, and ensure proper valve orientation. |

| Water Hammer / Noise | Use spring-assisted or dual-plate wafer valves for rapid, non-slam closure; consider adding water hammer arrestors. |

| Chatter / Fluttering | Size valves correctly to match system flow and pressure; ensure cracking pressure is appropriate to avoid rapid cycling. |

| Silt / Partial Closing | Maintain adequate flow rate; consider larger flow capacity valves or upstream cleaning systems to prevent sediment build-up. |

| Wear or Misalignment | Perform regular inspection and maintenance, verify proper installation and alignment, and replace springs or bearings as needed. |

Proactive Troubleshooting Steps

-

Routine Inspection: Listen for any unusual noises, check for leaks or vibration, and ensure all components move freely.

-

Pressure Testing: Conduct shell and seat closure tests per MSS SP-61 standards to ensure valve integrity.

-

Correct Any Flaws: If issues arise, depressurize and disassemble carefully to clean, align, or replace components.

-

Documentation: Log failures, repairs, and conditions to spot patterns and preempt recurring problems.

Conclusion

In fluid control systems where backflow prevention, efficiency, and reliability are critical, wafer check valves offer an ideal solution. Their compact design, lightweight build, and quick automatic closure make them easier to install and maintain compared to bulkier alternatives, while their versatility in materials, sizes, and configurations ensures compatibility with industries ranging from water treatment and HVAC to chemical, oil & gas, marine, and power generation. By choosing the right wafer check valve for your application—considering fluid type, pressure, temperature, and installation needs—you can improve system safety, minimize downtime, and extend equipment life, making wafer check valves a smart, cost-effective investment for modern fluid systems.