Check valve is an automatic valve that only allows the medium to flow in one direction to prevent accidents caused by reverse flow. There are many types of check valves, which can be divided into swing type, lifting type, inclined disc type, ball type, axial flow type, cut – off type and spring type according to different structures and applications. This article mainly introduces the use, advantages and disadvantages of swing check valves, and how to choose a suitable swing check valve.

The working principle of the swing check valve is: there is a disc in the valve body that can swing on a hinge or a rotating shaft. When the inflow pressure of the medium is higher than the opening pressure of the valve, the disc lifts up, the valve opens, and the medium can flow through smoothly. When inlet pressure drops, the disc drops and the valve closes, preventing any downstream reverse flow that might occur.

Advantages:

- Features low pressure drop and low turbulence, reducing energy loss and noise.

- Can handle large bore and high pressure applications.

- Can be manufactured in a variety of materials to suit different media and environments.

- Easy to install and maintain.

Disadvantages:

- Not suitable for pulsating or low flow applications.

- May close suddenly, causing water hammer or noise.

- May leak if the disc or seat is damaged or worn.

- May have slow reaction time to flow reversals.

Selection factors:

- The flow and velocity of the medium in the pipeline. The valve should be sized so that the flow rate is higher than the minimum flow rate (VMin) required to maintain the fully open position of the disc. In this way, the vibration and impact of the disc can be avoided.

- Pressure differential and turbulent flow across the valve. Valves should have low differential pressure and low turbulence to reduce energy loss and noise. Differential pressure depends on valve size, type, design and flow conditions.

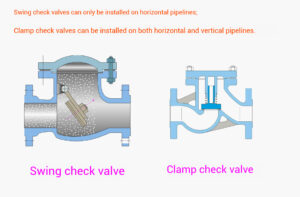

- Media type and nature. Valves should be compatible with media type, temperature, density, viscosity, corrosiveness, abrasiveness, etc. Valve materials, seals and coatings should be selected accordingly. Installation space and orientation. Valves should fit the available space and be installed in the correct orientation. Some swing check valves have a very short end – to – end distance for installation in small spaces. Some swing check valves can be installed in horizontal or vertical pipelines, while others can only be installed in horizontal pipelines.

If you are looking for high – quality, high – performance, high – reliability swing check valves, then WYVALVE is your best choice. WYVALVE is a professional check valve supplier and manufacturer with many years of experience and technology, providing you with various specifications, materials and designs of swing check valves to meet your various needs.

WYVALVE’s swing check valve has undergone strict quality control and testing, and complies with API, ASME, ANSI and other relevant standards to ensure your safety and efficiency. WYVALVE also provides high – quality after – sales service to solve any problems and difficulties for you.