I. Product Introduction

The pneumatic valve positioner is a core control accessory for pneumatic control valves. Designed to convert electrical or pneumatic control signals into precise mechanical displacement, it regulates the position of the valve stem. Acting as a “bridge” between control systems (e.g., DCS, PLC) and pneumatic actuators, it ensures that valves respond accurately to control commands.

Widely used in oil and gas, petrochemical, power generation, water treatment, and industrial automation projects (e.g., China Railway construction projects), the pneumatic valve positioner enhances the control accuracy, stability, and reliability of valve systems, which is critical for the regulation of process parameters (pressure, flow rate, temperature, liquid level).

II. Product Features

- LCD screen and 4 buttons for quick and easy automatic setting

- Partial Stroke Testing (PST) function

- Fault alarm function

- Built-in automatic/manual switch knob

- Self-diagnostic function

- IP66/NEMA4X protection rating

- Equipped with a large-flow pilot valve to speed up valve operation

- Shock-resistant and vibration-resistant design

III. Technical Data

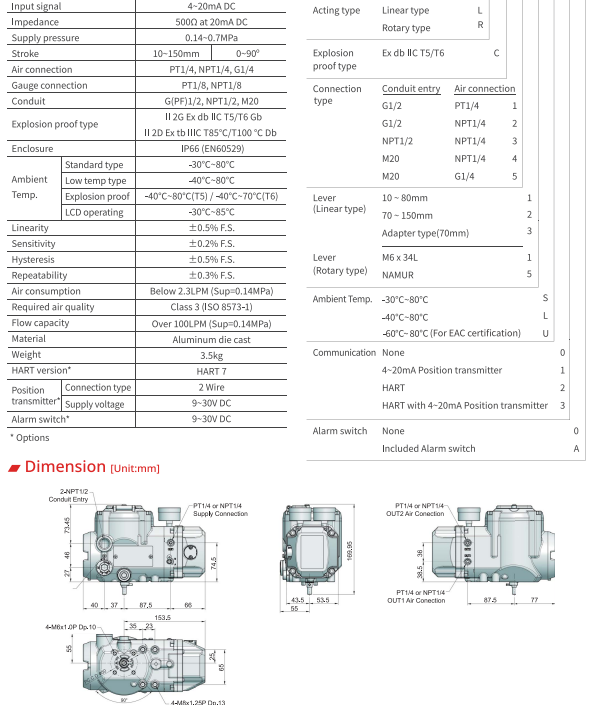

| Specification | Details |

|---|---|

| Input Current Range | 4~20mA DC |

| Internal Impedance | 500Ω (at 20mA DC) |

| Input Air Pressure Range | 0.14~0.7MPa |

| Stroke Range | Linear Stroke: 10~150mm, Rotary Stroke: 0~90º |

| Air Supply Connection Size | PT1/4, NPT1/4 |

| Pressure Gauge Connection Size | PT1/8, NPT1/8 |

| Electrical Connection Size | G(PF)1/2, NPT1/2 |

| Explosion-Proof Rating | EX db IIC T5/T6 |

| Enclosure Protection Rating | IP66 |

| Ambient Temperature (Normal Operation) | Standard Type: -30℃~85℃

Low-Temperature Type: -40℃~85℃ |

| Explosion-Proof Temperature Range | T5: -40℃~60℃ / T6: -40℃~40℃ |

| Linearity | ±0.5% F.S. |

| Sensitivity | ±0.2% F.S. |

| Hysteresis | ±0.5% F.S. |

| Repeatability | ±0.3% F.S. |

| Air Consumption | Less than 2.3LPM (Supply Pressure = 0.14MPa) |

| Air Supply Quality Grade | Grade 3 (ISO 8573-1) |

| Flow Rate | More than 100LPM (Supply Pressure = 0.14MPa) |

| Material | Die-Cast Aluminum, 316 Stainless Steel |

| Weight | 3.5kg |

四.The main shape and connection size