I. Product Introduction

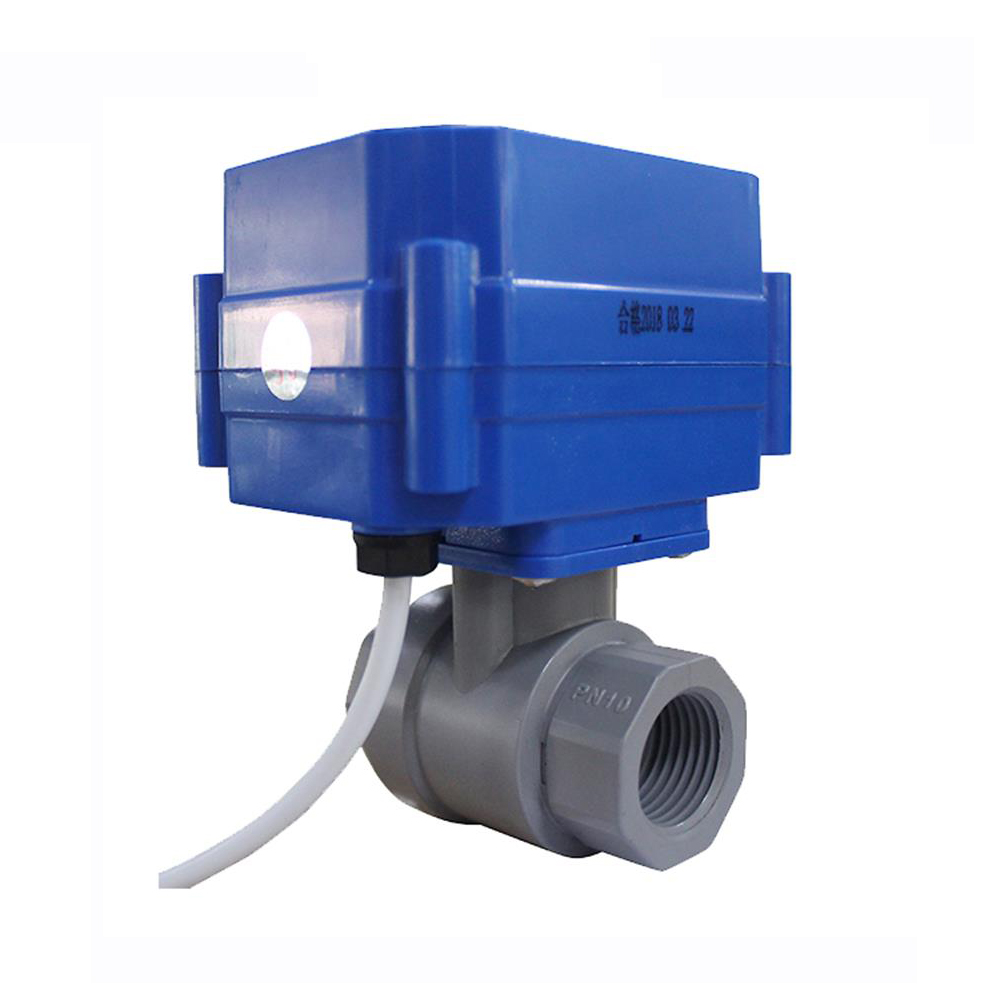

The 2 Way 3/4” UPVC Motorized Ball Valve is a specialized fluid control component that combines a 2-way straight-through ball valve core, 3/4-inch nominal diameter structure, and a high-performance miniaturized electrical actuator, with the valve body made of premium UPVC (Unplasticized Polyvinyl Chloride) material. It is mainly designed to realize automatic on-off control of non-corrosive or weakly corrosive fluid media in industrial, commercial and civil pipeline systems, such as water supply and drainage, chemical reagent transportation, water treatment, and irrigation systems.

Compared with traditional manual ball valves, this product adopts electrical actuator drive, which can realize remote control, timing control and linkage control with the control system, effectively improving the automation level of the pipeline system. The 3/4-inch specification is a common size in medium and small flow pipeline systems, and the UPVC material gives the valve excellent corrosion resistance and economy, making it widely used in scenarios with strict requirements on cost and corrosion resistance.

II. Product Features

-

Excellent Corrosion Resistance: The valve body, ball core and sealing parts are made of UPVC material, which has strong resistance to most non-oxidizing acids, alkalis, salts and organic solvents (such as hydrochloric acid, sulfuric acid with low concentration, sodium hydroxide solution, etc.). It does not rust or corrode, and has a long service life in corrosive medium environments, which is far superior to traditional metal valves.

-

High Automation and Convenience: Equipped with a dedicated miniaturized electrical actuator, it supports multiple control modes such as on-site button operation, remote 220V/24V signal control, and PLC linkage control. It can realize automatic switching without manual on-site operation, which is especially suitable for scenarios where the installation position is narrow, high or difficult to reach manually.

-

Stable Sealing and Low Flow Resistance: The 2-way straight-through structure design ensures smooth fluid flow, with a flow resistance coefficient as low as 0.1, which effectively reduces energy consumption of the pipeline system. The valve adopts a soft-sealing structure (UPVC+EPDM), which has good sealing performance, and the leakage rate is lower than 0.01L/min, ensuring no medium leakage.

-

Light Weight and Easy Installation: UPVC material has the characteristic of light weight (density is about 1.4g/cm³, only 1/5 of carbon steel), so the overall weight of the valve is light, which is convenient for transportation and on-site installation. The connection mode adopts standard thread or flange connection, which is simple and fast, and can be completed by ordinary tools without professional installation equipment.

-

Reliable Safety Protection: The electrical actuator is equipped with overload protection and limit position protection functions. When the valve is stuck or reaches the full-open/full-close position during operation, the actuator will automatically cut off the power supply to avoid burnout of the motor or damage to the valve core. At the same time, the actuator has a protection grade of IP65, which can adapt to humid and dusty on-site environments.

-

Economical and Practical: UPVC material has low raw material cost, and the product price is more competitive compared with stainless steel or alloy valves. At the same time, the valve has simple structure, few wearing parts, and almost no maintenance in the later period, which greatly reduces the total cost of ownership.

III. Technical Data

|

Technical Parameter

|

Specification Details

|

|---|---|

|

Valve Type

|

2 Way Straight-through Motorized Ball Valve

|

|

Nominal Diameter (DN/Inch)

|

DN20 (3/4”)

|

|

Nominal Pressure (PN)

|

PN1.0MPa, PN1.6MPa

|

|

Valve Body Material

|

Premium UPVC (GB/T 10002.1 standard)

|

|

Ball Core Material

|

UPVC, Reinforced UPVC (optional)

|

|

Sealing Material

|

EPDM, FKM (Fluororubber, optional for strong corrosion)

|

|

Electrical Actuator Power Supply

|

AC 220V±10% 50/60Hz; DC 24V±10% (customizable)

|

|

Actuator Power

|

10W~30W (depending on pressure grade)

|

|

Control Mode

|

On-off control (open/close signal); Feedback signal (optional, 4-20mA)

|

|

Switching Time

|

5s~15s (full stroke)

|

|

Working Temperature Range

|

-10℃~60℃ (EPDM seal); -10℃~80℃ (FKM seal)

|

|

Leakage Rate

|

≤0.01L/min (water pressure test at 1.1 times nominal pressure)

|

|

Actuator Protection Grade

|

IP65; IP67 (optional for wet environment)

|

|

Connection Mode

|

Threaded connection (NPT, G1/2”; conforms to ISO 228 standard); Flanged connection (PN1.0/1.6, conforms to GB/T 9113 standard, optional)

|

|

Applicable Medium

|

Clean water, sewage, tap water, chemical solutions (pH 2-12), agricultural irrigation water, etc.

|

|

Actuator Accessories (Optional)

|

Position feedback switch, manual override device, waterproof junction box

|