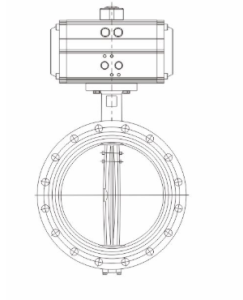

I. Product Introduction

The Pneumatic Soft Seal Flange Butterfly Valve is a high-performance control valve widely used in fluid conveying systems, which integrates pneumatic actuation, soft sealing technology and flange connection. It takes compressed air as the power source to drive the valve disc to rotate around the valve shaft, so as to realize the opening and closing or regulation of the pipeline medium. The soft sealing structure (usually made of elastic materials such as EPDM, NBR and PTFE) ensures excellent sealing performance of the valve, effectively preventing medium leakage and ensuring the stability and safety of the system operation.

This type of valve is designed with a flange connection mode, which is convenient for quick installation and disassembly with the pipeline, and has good compatibility with various standard pipelines. It is suitable for a variety of media, including water, sewage, oil, gas, chemical reagents and other non-corrosive or weakly corrosive media, and is widely used in petroleum, chemical, water treatment, power generation, metallurgy, food and beverage, pharmaceutical and other industries. Whether it is used for on-off control of general working conditions or precise flow regulation of special working conditions, it can show stable and reliable performance.

II. Product Features

-

Excellent Sealing Performance: The valve adopts a soft sealing structure, and the sealing ring is made of high-quality elastic materials with good wear resistance, corrosion resistance and aging resistance. It can form a tight fit with the valve disc and valve seat under the action of preload, realizing zero leakage of the medium. Even in the case of low pressure or small flow, it can maintain reliable sealing performance, which is far superior to the traditional hard sealing butterfly valve.

-

High Response Speed & Stable Operation: Driven by a high-quality pneumatic actuator, the valve has the characteristics of fast opening and closing speed, usually completing the opening and closing action within a few seconds. The actuator is equipped with a reasonable buffer structure, which can effectively reduce the impact force during the operation of the valve disc, avoid mechanical damage caused by violent collision, and ensure the stable operation of the valve and extend its service life.

-

Convenient Installation & Maintenance: The flange connection design is in line with international standards (such as GB, ANSI, DIN, etc.), which can be directly connected with the matching pipeline without additional adapter parts, greatly simplifying the installation process. At the same time, the internal structure of the valve is simple and compact, the key components are easy to disassemble and assemble, and the daily maintenance (such as replacing the sealing ring, cleaning the valve cavity, etc.) can be completed quickly, reducing the maintenance cost and downtime.

-

Wide Application Range: It can adapt to different medium types and working conditions. The applicable medium temperature ranges from -40℃ to 120℃ (adjustable according to the material of the sealing ring), and the applicable nominal pressure is usually PN1.0-PN2.5 (special pressure grades can be customized according to needs). In addition, it can be equipped with different types of positioners and solenoid valves to realize automatic control and remote monitoring, meeting the needs of intelligent production systems.

-

Energy Conservation & Environmental Protection: The valve disc has a small flow resistance coefficient during operation, which can reduce the energy consumption of the pump or compressor in the system and achieve the effect of energy conservation. The selected sealing materials and valve body materials are non-toxic, harmless and in line with environmental protection standards, which will not cause pollution to the medium and the environment, and are suitable for industries with strict environmental protection requirements (such as food, pharmaceutical, water treatment, etc.).

-

Strong Structural Reliability: The valve body is usually made of cast iron, cast steel, stainless steel and other high-strength materials, which have good mechanical properties and pressure-bearing capacity, and can withstand the impact of medium pressure and external force. The valve shaft is treated with precision machining and anti-corrosion, which has high rigidity and wear resistance, avoiding deformation or damage during long-term operation.

III. Technical Data

|

Technical Parameter

|

Specification

|

|---|---|

|

Nominal Diameter (DN)

|

DN50 – DN1200 (special specifications can be customized)

|

|

Nominal Pressure (PN)

|

PN1.0, PN1.6, PN2.5 (MPa); Class 150 (PSI) for ANSI standard

|

|

Applicable Medium

|

Water, sewage, oil, gas, weak acid, weak alkali, chemical reagents, etc. (non-corrosive or weakly corrosive media)

|

|

Medium Temperature Range

|

-40℃ – 80℃ (EPDM seal); -20℃ – 120℃ (NBR seal); -10℃ – 180℃ (PTFE seal)

|

|

Valve Body Material

|

Cast Iron (HT200), Ductile Iron (QT450), Carbon Steel (WCB), Stainless Steel (304, 316, 316L)

|

|

Valve Disc Material

|

Carbon Steel, Stainless Steel (304, 316, 316L), Cast Iron with Rubber Lining

|

|

Sealing Ring Material

|

EPDM, NBR, PTFE, FKM (Viton)

|

|

Driving Mode

|

Pneumatic (single-acting, double-acting); optional with solenoid valve, positioner, limit switch

|

|

Air Source Pressure

|

0.4 – 0.6 MPa (compressed air)

|

|

Opening and Closing Time

|

3 – 15 seconds (depending on nominal diameter and actuator type)

|

|

Sealing Performance

|

Zero leakage (meets the requirements of GB/T 13927-2008 leakage test standard)

|

|

Connection Standard

|

GB/T 9113 (China), ANSI B16.5 (US), DIN EN 1092-1 (Europe), JIS B2220 (Japan)

|

|

Working Life

|

≥ 100,000 times of opening and closing (under normal working conditions)

|

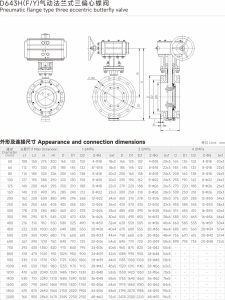

四.The main shape and connection size