I. Product Introduction

The Lug (Counterclamp) Type Worm Gear Butterfly Valve (Centreline) is a high-performance industrial valve meticulously designed and manufactured in compliance with API (American Petroleum Institute) standards. Adopting a centreline structure, the valve features perfect coincidence between the butterfly plate axis and the centerline of the valve body/seat, which effectively minimizes operational torque and ensures stable sealing performance during the service life.

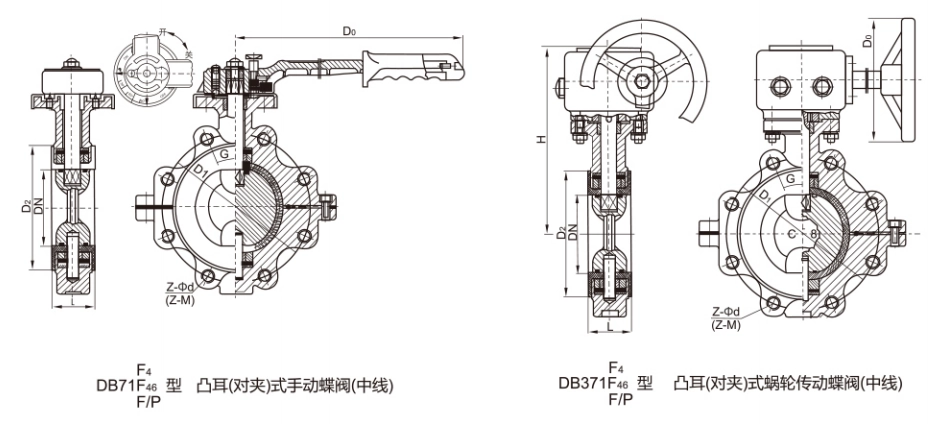

This valve series offers three distinct lining configurations to meet diverse industrial media and working condition requirements: the DB71F46 fully lined type, DB71F4 fully lined type, and DB71F/P half-lined type. It is widely applicable to fluid control systems in petroleum, chemical, metallurgy, and other industries, capable of regulating and isolating corrosive, abrasive, or general media with high reliability.

The valve is equipped with a worm gear drive mechanism, which provides smooth and labor-saving operation, precise flow control, and excellent anti-theft and anti-misoperation performance, making it suitable for both manual and automated control scenarios.

II. Product Features

-

Standard-compliant Design & ManufacturingThe valve is engineered and produced in accordance with API 609 and GB/T 12238 standards for centreline butterfly valves, ensuring compatibility with international industrial systems and reliable quality.

-

Centreline Structure AdvantageThe coaxial design of the butterfly plate axis and valve body/seat centerline eliminates the offset torque during valve opening and closing, reduces wear between the butterfly plate and seat, and extends the service life of sealing components.

-

Diversified Lining Configurations

- DB71F46 Fully Lined Type: Full lining of valve body and butterfly plate; integrated structure of butterfly plate and butterfly plate shaft, enhancing structural rigidity and sealing integrity.

- DB71F4 Fully Lined Type: Full lining of valve body and butterfly plate; assembled structure of butterfly plate and disk shaft, facilitating maintenance and replacement of parts.

- DB71F/P Half-lined Type: Full lining of valve body; stainless steel butterfly plate without lining; assembled structure of butterfly plate and butterfly plate shaft, balancing corrosion resistance and mechanical strength.

-

Flexible Drive OptionsBased on the worm gear drive core, the valve can be configured with different operation modes, including handlebar rotation, worm-gear rotation, pneumatic drive, and electric drive, adapting to various application scenarios from local manual control to remote automated control.

-

Reliable Sealing PerformanceThe lining/seat adopts high-performance materials such as PTFE (F4), PCTFE (F3), FEP (F46), PFA, and PO, which have excellent corrosion resistance, high and low temperature resistance, and self-lubricating properties, ensuring zero leakage of the valve under rated working conditions.

-

Standardized Connection & DimensionFlange size complies with HG/T 20592 and ASME B 16.5 (for NPS≤24), and structure length conforms to GB/T 12221 and API 609, enabling easy installation and replacement with valves of other brands.

III. Technical Data

1. Implementation Standards

| Standard Category | Applicable Standards |

|---|---|

| Design and Manufacturing | GB/T 12238, API 609 (Centreline) |

| Structure Length | GB/T 12221, API 609 |

| Flange Size | HG/T 20592, ASME B 16.5 (NPS≤24) |

| Pressure Test | GB/T 13927, API 598 |

| Symbolization | GB/T 12220, MSS SP-25 |

| Filling | JB/T 7928, API 609 |

2. Basic Specifications

| Parameter | Details |

|---|---|

| Nominal Pressure | ANSI 150Lb |

| Nominal Diameter | NPS 2~24 |

3. Model Classification by Drive Mode & Lining Type

| Drive Mode | Model | Lining Type |

|---|---|---|

| Handlebar Rotation | DB71F/P | Half-lined |

| DB71PFA | Fully lined | |

| D871F4 | Fully lined | |

| Da71F46 | Fully lined | |

| Worm-gear Rotation | DB371F/P | Half-lined |

| DB371PFA | Fully lined | |

| DB371F4 | Fully lined | |

| Da371F46 | Fully lined | |

| Pneumatic Drive | DB671F/P | Half-lined |

| DB671PFA | Fully lined | |

| Dg671F4 | Fully lined | |

| Dg671F46 | Fully lined | |

| Electric Drive | De971F/P | Half-lined |

| DB971PFA | Fully lined | |

| De971F | Fully lined | |

| De971F46 | Fully lined |

4. Main Parts and Components Material Table

| Serial Number | Part Name | Gray Cast Iron (Z) | Carbon Steel (C) | Stainless Steels (P) | Ultra-low Carbon Stainless Steel (R) | Stainless Steels (PL) | Ultra-low Carbon Stainless Steel (RL) |

|---|---|---|---|---|---|---|---|

| 1 | Upper and Lower Valve Body | A126 C.135A | A216 WCB | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| 2 | Butterfly Plate | – | A216 WCB/A105 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| 3 | Butterfly Plate Shaft | – | A182 F6 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| 4 | Lining/Seat | PTFE(F4), PCTFE(F3), FEP(F46), PFA, PO | |||||

| 5 | O-ring | FPM (Fluoroelastomer) | FPM (Fluoroelastomer) | ||||

| 6 | Pad | SiR (Silicone Rubber) | SiR (Silicone Rubber) | ||||

| 7 | Adjustable Positioning Seat | – | A182 F304 | A182 F304 | A182 F304 | A182 F304L | A182 F316L |

| 8 | Bolt (Male Component of Nut and Bolt) | – | A193 B7 | A193 B8M | A193 B8M | A193 B8M | A193 B8M |

| 9 | Nut (Female Component of Nut and Bolt) | – | A194 2H | A194 8 | A194 8 | A194 8 | A194 8 |

| 10 | Actuator Housing | ZL101 (Casting Aluminum Alloy) |

Ⅳ.The main shape and connection size

Main parts and components material table

| serial number | Part Name | gray cast iron | carbon steel | stainless steels | Ultra-low carbon stainless steel | ||

| Z | C | P | R | PL | RL | ||

| 1 | Upper and lower valve body | A126 C.135A | A216 WCB | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| 2 | butterfly plate | A216 WCB | A105 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| 3 | Butterfly plate shaft | A182 F6 | A182 F6 | A182 F304 | A182 F316 | A182 F304L | A182 F316L |

| 4 | Lining/seat | PTEE(F4)PCTFE(F3)FEP(F46)PFA(Soluble polytetrafluoroethylene)PO(polyolefin) | |||||

| 5 | O-ring | FPM(fluoroelastomer) | FPM(Fluoroelastomer) | ||||

| 6 | pad | SiR(silicone rubber) | SiR(silicone rubber) | ||||

| 7 | Adjustable Positioning Seat | A182 F304 | A182 F304 | A182 F304 | A182 F304 | A182 F304L | A182 F316L |

| 8 | bolt (male component of nut and bolt) | A193 B7 | A193 B7 | A193 B8M | A193 B8M | A193 B8M | A193 B8M |

| 9 | nut (female component of nut and bolt) | A1942H | A1942H | A1948 | A1948 | A1948 | A1948 |

| 10 | video game controller | ZL101(Casting Aluminum Alloy) | |||||

Main connection dimensions and weight

| Nominal diameter | standard value | reference point | |||||||||

| DN

(mm) |

NPS

(inch) |

L | D | D1 | D2 | f | b | Z-Φd | Do | H | W(kg |

| Class 150Lb | |||||||||||

| 50 | 2 | 43 | – | 120.7 | 92.1 | 3.5 | – | 4-Φ19 | 200 | 150 | 5 |

| 65 | 21/2 | 46 | – | 139.7 | 104.8 | 3.5 | – | 4-Φ19 | 250 | 160 | 7 |

| 80 | 3 | 46 | – | 152.4 | 127 | 3.5 | – | 4-Φ19 | 2580 | 170 | 10 |

| 100 | 4 | 52 | – | 190.5 | 157.2 | 3.5 | – | 8-Φ19 | 300 | 185 | 14 |

| 125 | 5 | 56 | – | 215.9 | 185.7 | 3.5 | – | 8-Φ22 | 300 | 210 | 22 |

| 150 | 6 | 56 | – | 241.3 | 215.9 | 4 | – | 8-Φ22 | 200* | 230 | 32 |

| 200 | 8 | 60 | – | 298.5 | 269.9 | 4 | – | 8-Φ22 | 240* | 285 | 66 |

| 250 | 10 | 68 | – | 362 | 323.8 | 4 | – | 12-Φ25 | 240* | 325 | 80 |

| 300 | 12 | 78 | – | 431.8 | 381 | 4.5 | – | 12-Φ25 | 280* | 360 | 94 |

| 350 | 14 | 78 | – | 476.3 | 412.8 | 4.5 | – | 12-Φ28.6 | 280* | 430 | 125 |

| 400 | 16 | 102 | – | 539.8 | 469.9 | 5 | – | 16-Φ28.6 | 320* | 475 | 150 |

| 450 | 18 | 114 | – | 577.9 | 533 | 5 | – | 16-Φ31.8 | 320* | 525 | 172 |

| 500 | 20 | 127 | – | 635 | 584 | 6 | – | 20-Φ31.8 | 360* | 565 | 225 |

| 600 | 24 | 154 | – | 749.3 | 692 | 6 | – | 20-Φ34.9 | 360* | 630 | 290 |

The flange size in the table is according to ASME B16.5 when NPS≤24, and according to ASME B16.47 when NPS>24.

Flange size D, D1, D2, Z-φd, f, d, the value is the standard flange size connected with the butterfly valve, the size code in the sketch is only part of it.