I. Product Introduction

The ball of the trunnion ball valve is fixed and supported by upper and lower trunnions. Compared with floating ball valves, it features higher pressure resistance and impact resistance, making it suitable for large-diameter and high-pressure industrial pipeline applications such as oil and gas pipelines, chemical engineering, and other related fields.

II. Product Features

- Stable Structure

The ball is secured by upper and lower trunnions, which eliminates displacement during operation and ensures excellent sealing performance even under high pressure and impact loads.

- Superior Pressure & Impact Resistance

Outperforms floating ball valves in withstanding high pressure and external impact, ideal for harsh working conditions in oil, gas, and chemical industries.

- Broad Material Compatibility

Key components are made of high-quality alloys, stainless steel, and advanced polymers, ensuring corrosion resistance and durability in various media environments.

- Wide Application Scope

Designed for large-diameter, high-pressure industrial pipelines, meeting the stringent requirements of oil and gas transmission, chemical processing, and heavy industry.

III. Technical Data

1. Main Components and Materials (ASTM Standards)

| No. | Component Name | Materials |

|---|---|---|

| 1 | Body | A216-WCB, A352-LCB, A351-CF8M, CF3, CF3M, A52-LCB, LCC, 31803 |

| 2 | Spring | 60Si2Mn, SS304, SS316, 17-7PH, Inconel X750 |

| 3 | Seat | Polytetrafluoroethylene (PTFE), Reinforced Polytetrafluoroethylene (RPTFE), Polyether Ether Ketone (PEEK), Poly(p-phenylene oxide) (PPL) |

| 4 | Ball | F304, F316, F316L, A105+ENP, F51LF2+ENP, 1Cr18Ni9Ti |

| 5 | Orifice | 45*, A182-F6, F304, F316, F316L |

| 6 | Gland Packing | PTFE, Graphite |

| 7 | Stem | A105+ENP, A182-F6, F304, F316, F316L |

| 8 | Gland | A216-WCB, A351-CF8 |

| 9 | Upstream Retainer | A216-WCB |

| 10 | Cover Plate | A105+ENP, A182-F304, F316, F316L |

| 11 | O-Ring | Fluororubber, Fluororubber |

| 12 | Sliding Bearing | +PTFE, PTFE & Stainless Steel, 316+PTFE |

| 13 | Stud | 35#, B7, B8, B8M, L7 |

| 14 | Nut | 25#, 2H, 8, 8M, 4 |

| 15 | Bonnet | A216-WCB, CF8, CF8M, CF3M, A352-LCB |

| 16 | Seat Ring | A105+ENP, A182-F6, F304, F316, F316L |

| 17 | Gasket | PTFE, Graphite + Stainless Steel |

| 18 | Bolt | 35#, B7, B8, B8M, L7 |

| 19 | Retaining Ring | A105+ENP, A182-F6, F304, F316, F316L |

| 20 | Bottom Cover | A105+ENP, A182-F304, F316, F316L |

| 21 | Pressure Relief Screw | 35#, B7, B8, B8M |

2. Design and Manufacturing Standards

| Category | Standards |

|---|---|

| Design Reference | API Series |

| Design Standard | API 6D, ANSI B16.34, BS5351 |

| Body | ANSI B16.10 |

| End Flange | ANSI B16.5, B16.47 |

| BW Ends | ANSI B16.25 |

| Testing and Inspection | API 6D, API 598 |

| Fire Safety | API 607 |

3. Test Pressure (API 598) (Unit: MPa)

| Nominal Pressure (Class) | Shell Test Pressure | Seat Test Pressure | Hydrostatic Test Pressure |

|---|---|---|---|

| Class 150 | 3.0 | 2.2 | 0.6 |

| Class 300 | 7.7 | 5.7 | – |

| Class 600 | 15.4 | 11.3 | – |

| Class 900 | 23.0 | 16.9 | – |

| Class 1500 | 38.3 | 28.1 | – |

| Class 2500 | 63.9 | 46.9 | – |

4. Minimum Test Duration (API 598) (Unit: Seconds)

| NPS (inch) | Shell Test | Seat Test | Hydrostatic Test |

|---|---|---|---|

| ≤ 2 | 15 | 15 | 15 |

| 2-1/2 ~ 6 | 60 | 60 | 60 |

| 8~12 | 120 | 120 | 120 |

| ≥ 14 | 300 | 120 | 120 |

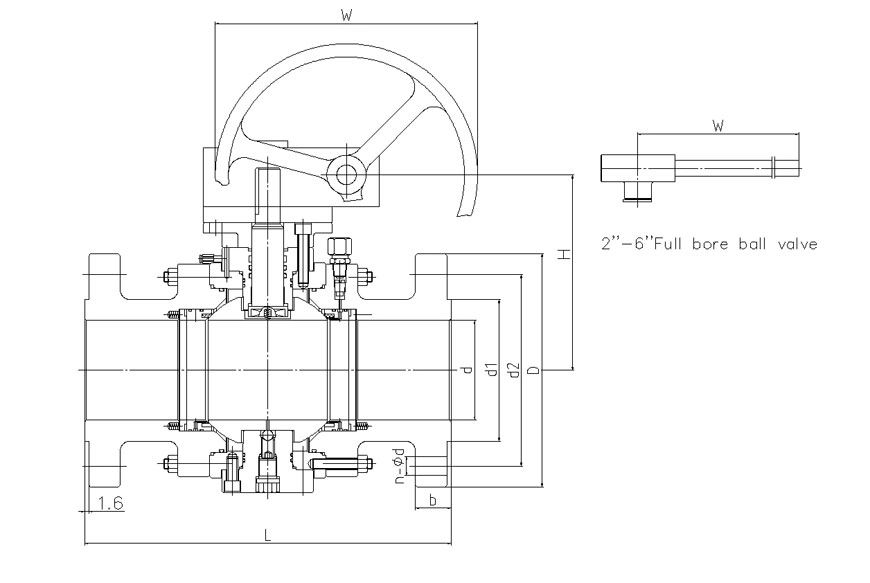

Ⅳ.The main shape and connection size

Class150 3 piece ball valves

| NPS | in | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| d | mm | 51 | 64 | 76 | 102 | 152 | 203 | 254 | 305 | 337 | 387 | 438 | 489 | 591 |

| L(RF) | mm | 178 | 190 | 203 | 229 | 394 | 457 | 533 | 610 | 686 | 762 | 864 | 914 | 1016 |

| d1 | mm | 92 | 105 | 127 | 157 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 |

| d2 | mm | 120.5 | 139.5 | 152.5 | 190.5 | 241.5 | 298.5 | 362 | 432 | 476 | 540 | 578 | 635 | 749.5 |

| D | mm | 152 | 178 | 190 | 229 | 279 | 343 | 406 | 483 | 533 | 597 | 635 | 699 | 813 |

| b | mm | 16 | 18 | 19 | 24 | 26 | 29 | 31 | 32 | 35 | 37 | 40 | 43 | 48 |

| n-Фd | mm | 4-19 | 4-19 | 4-19 | 8-19 | 8-22 | 8-22 | 12-25 | 12-25 | 12-29 | 16-29 | 16-32 | 20-32 | 20-35 |

| H | mm | 176 | 200 | 215 | 252 | 330 | 448 | 505 | 556 | 620 | 700 | 750 | 805 | 1110 |

| W | mm | 350 | 400 | 400 | 500 | 1000 | 300 | 350 | 400 | 500 | 500 | 500 | 500 | 500 |

Class300 3 piece ball valves

| NPS | in | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| d | mm | 51 | 64 | 76 | 102 | 152 | 203 | 254 | 305 | 337 | 387 | 432 | 483 | 584 |

| L(RF) | mm | 216 | 241 | 283 | 305 | 403 | 502 | 568 | 648 | 762 | 838 | 914 | 991 | 1143 |

| d1 | mm | 92 | 105 | 127 | 157 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 |

| d2 | mm | 127 | 149 | 168.5 | 200 | 270 | 330 | 387.5 | 451 | 514.5 | 571.5 | 628.5 | 686 | 813 |

| D | mm | 165 | 190 | 210 | 254 | 318 | 381 | 445 | 521 | 584 | 648 | 711 | 775 | 914 |

| b | mm | 23 | 26 | 29 | 32 | 37 | 42 | 48 | 51 | 54 | 58 | 61 | 64 | 70 |

| n-Фd | mm | 8-19 | 8-22 | 8-22 | 8-22 | 12-22 | 12-25 | 16-29 | 16-32 | 20-32 | 20-35 | 24-35 | 24-35 | 24-41 |

| H | mm | 176 | 200 | 215 | 252 | 330 | 448 | 505 | 556 | 620 | 700 | 750 | 805 | 1110 |

| W | mm | 350 | 400 | 400 | 500 | 1000 | 300 | 350 | 400 | 500 | 500 | 500 | 500 | 500 |

Class600 3 piece ball valves

| NPS | in | 2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| d | mm | 51 | 76 | 102 | 127 | 152 | 200 | 248 | 298 | 327 | 375 | 419 | 464 | 559 |

| L(RF) | mm | 292 | 356 | 432 | 508 | 559 | 660 | 787 | 838 | 889 | 991 | 1092 | 1194 | 1397 |

| d1 | mm | 92 | 127 | 157 | 186 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 |

| d2 | mm | 127 | 168.5 | 216 | 267 | 292 | 349 | 432 | 489 | 527 | 603 | 654 | 724 | 838 |

| D | mm | 165 | 210 | 273 | 330 | 356 | 419 | 508 | 559 | 603 | 686 | 743 | 813 | 940 |

| b | mm | 26 | 32 | 38 | 45 | 48 | 56 | 64 | 67 | 70 | 77 | 83 | 89 | 102 |

| n-Фd | mm | 8-19 | 8-22 | 8-25 | 8-29 | 12-29 | 12-32 | 16-35 | 20-35 | 20-38 | 20-41 | 20-44 | 24-44 | 24-52 |

| H | mm | 192 | 279 | 315 | 320 | 323 | 381 | 518 | 568 | 665 | 730 | 795 | 825 | 973 |

| W | mm | 600 | 1000 | 1500 | 1500 | 1500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 |

Class900 3 piece ball valves

| NPS | in | 2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 |

| d | mm | 47 | 73 | 98 | 121 | 146 | 190 | 234 | 282 | 311 | 354 | 400 | 444 | 533 |

| L(RF) | mm | 368 | 381 | 457 | 559 | 610 | 737 | 838 | 965 | 1029 | 1130 | 1219 | 1321 | 1549 |

| L(RTJ) | mm | 371 | 384 | 460 | 562 | 613 | 740 | 841 | 968 | 1039 | 1140 | 1232 | 1334 | 1568 |

| d1 | mm | 92 | 127 | 157 | 186 | 216 | 270 | 324 | 381 | 413 | 470 | 533 | 584 | 692 |

| d2 | mm | 165 | 190.5 | 235 | 279.4 | 317.5 | 393.7 | 469.9 | 533.4 | 558.8 | 615.9 | 685.8 | 749.3 | 901.7 |

| D | mm | 216 | 241 | 292 | 349 | 381 | 470 | 545 | 610 | 640 | 705 | 785 | 855 | 1040 |

| b | mm | 38.5 | 38.5 | 44.5 | 51 | 56 | 64 | 70 | 79.5 | 86 | 89 | 102 | 108 | 140 |

| n-Фd | mm | 8-26 | 8-26 | 8-32 | 8-35 | 12-32 | 12-39 | 16-39 | 20-39 | 20-42 | 20-45 | 20-51 | 20-54 | 20-67 |

| H | mm | 192 | 279 | 315 | 320 | 323 | 381 | 518 | 568 | 665 | 730 | 795 | 825 | 973 |

| W | mm | 600 | 1000 | 1500 | 1500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 | 500 |