I. Product Introduction

II. Product Features

-

Standard Compliance & Compatibility

Strictly designed/manufactured per ANSI B16.34, BS1868; face-to-face dimensions follow ANSI B16.10, and flange dimensions align with ANSI B16.5—ensuring full compatibility with ANSI/ASME pipeline systems.

-

Reliable Backflow Prevention

The swing disc structure (paired with precision sealing surfaces) achieves tight closure when flow reverses, minimizing leakage risk; the disc’s self-closing design (gravity-driven) ensures rapid response to flow changes.

-

Broad Material Adaptability

Main parts (body, bonnet, wedge) offer multiple material options (e.g., WCB, CF8, CF8M, CF3M), adapting to different temperatures, pressures, and corrosive media (e.g., nitric acid, acetic acid).

-

Durable Sealing & Structural Stability

Equipped with high-quality fasteners (e.g., A193-B7 bolts, A194-2H nuts) and precision-machined sealing surfaces; the back seal test (per API 598) ensures long-term sealing reliability under high-pressure conditions.

-

Low Flow Resistance & Easy Maintenance

The streamlined flow path reduces pressure loss during forward flow; the flange-connected bonnet allows convenient disassembly for disc, seal, and internal part inspection/maintenance.

III. Technical Data

1. Standards

| Category | Applicable Standards |

|---|---|

| Design & Manufacture | BS1868, ANSI B16.34 |

| Face-to-Face Dimensions | ANSI B16.10 |

| End Flange Dimensions | ANSI B16.5 |

| Pressure-Temperature Rating | ANSI B16.34 |

| Pressure Test | API 598 |

2. Test Pressure

| Pressure Class | Shell Test | Seal Test | Back Seal Test | Air Seal Test |

|---|---|---|---|---|

| MPa (Ibf/in²) | MPa (Ibf/in²) | MPa (Ibf/in²) | MPa (Ibf/in²) | |

| 150 | 3.1 (450) | 2.2 (315) | 2.2 (315) | 0.5~0.7 (60~100) |

| 300 | 7.8 (1125) | 5.6 (815) | 5.6 (815) | – |

| 400 | 10.3 (1500) | 7.6 (1100) | 7.6 (1100) | – |

| 600 | 15.3 (2225) | 11.2 (1630) | 11.2 (1630) | – |

| 900 | 23.1 (3350) | 16.8 (2440) | 16.8 (2440) | – |

| 1500 | 38.4 (5575) | 28.1 (4080) | 28.1 (4080) | – |

| Test Medium | Water | Air | Air | Air |

3. Materials for Main Parts

| Part Name | Material Options |

|---|---|

| Body, Bonnet | A216 WCB, A352 LCB, A217 WC6, A217 WC9, A217 C5, A351 CF8, A351 CF8M, A351 CF3, A351 CF3M |

| Wedge | Same as Body/Bonnet material |

| Arm, Yoke | Same as Body/Bonnet material |

| Arm Pin | A182 F6, A182 F304, A182 F316, A182 F304L, A182 F316L |

| Bonnet Bolt | A193-B7, A320-L7, A193-B8 |

| Nut | A194-2H, A194-7, A194-8 |

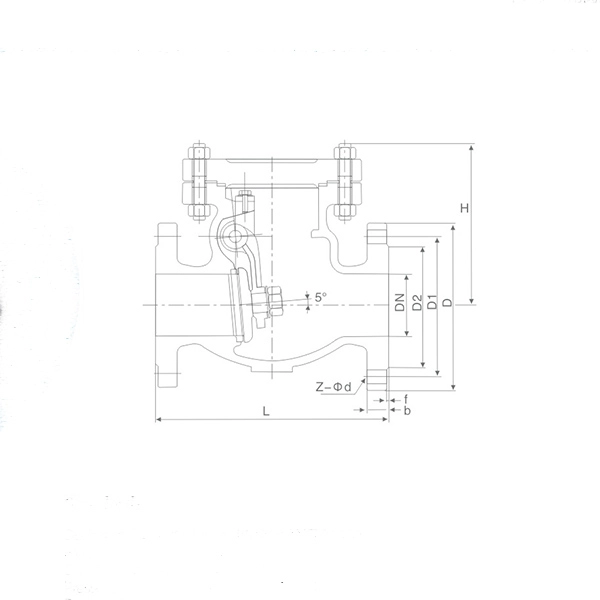

Ⅳ.The main shape and connection size

| Type | Size(mm | Dimension(mm) | |||||||

| Inch | DN | L | D | D1 | D2 | b | z- Φd | H | |

| H

H44W-150Lb Y |

1″ | 25 | 127 | 108 | 79.5 | 51 | 12 | 4- Φ15 | 90 |

| 11/2″ | 40 | 165 | 127 | 98.5 | 73 | 15 | 4- Φ15 | 115 | |

| 2″ | 50 | 203 | 152 | 120.7 | 92 | 16 | 4- Φ19 | 150 | |

| 21/2″ | 65 | 216 | 177.8 | 139.7 | 104.7 | 18 | 4- Φ19 | 160 | |

| 3″ | 80 | 241 | 190.5 | 152.4 | 127 | 19 | 4- Φ19 | 180 | |

| 4″ | 100 | 292 | 229 | 190.5 | 157 | 24 | 8- Φ19 | 220 | |

| 5″ | 125 | 330 | 254 | 216 | 185.7 | 26 | 8- Φ22 | 280 | |

| 6″ | 150 | 356 | 279 | 241.3 | 216 | 26 | 8- Φ22 | 340 | |

| 8″ | 200 | 495 | 343 | 298.5 | 270 | 29 | 8- Φ22 | 400 | |

| 10″ | 250 | 622 | 406 | 362 | 324 | 31 | 12- Φ25 | 460 | |

| 12″ | 300 | 698 | 483 | 432 | 381 | 32 | 12- Φ25 | 530 | |

| 14″ | 350 | 787 | 533 | 476.3 | 413 | 35 | 12- Φ29 | 580 | |

| 16″ | 400 | 864 | 597 | 540 | 470 | 37 | 16- Φ29 | 600 | |

| 18″ | 450 | 978 | 635 | 578 | 533.4 | 40 | 16- Φ32 | 650 | |

| 20″ | 500 | 978 | 698.5 | 635 | 584 | 43 | 20- Φ32 | 700 | |

| 24″ | 600 | 1295 | 813 | 749.3 | 692 | 48 | 20- Φ35 | 780 | |

| 28″ | 700 | 1448 | 927 | 863.6 | 800 | 72 | 28- Φ35 | 850 | |

| 30″ | 800 | 1524 | 984 | 914.4 | 857 | 75 | 28- Φ35 | 920 | |

| H

H44W-300Lb Y |

2″ | 50 | 267 | 165 | 127 | 92 | 23 | 8- Φ19 | 170 |

| 21/2″ | 65 | 292 | 190.5 | 149.4 | 104.7 | 26 | 8- Φ22 | 180 | |

| 3″ | 80 | 318 | 210 | 168.2 | 127 | 29 | 8- Φ22 | 210 | |

| 4″ | 100 | 356 | 254 | 200.2 | 157 | 32 | 8- Φ22 | 290 | |

| 5″ | 125 | 400 | 279 | 235 | 185.7 | 35 | 8- Φ22 | 290 | |

| 6″ | 150 | 444 | 318 | 270 | 216 | 37 | 12- Φ22 | 350 | |

| 8″ | 200 | 533 | 381 | 330 | 270 | 42 | 12- Φ25 | 430 | |

| 10″ | 250 | 622 | 445 | 387.5 | 324 | 48 | 16- Φ29 | 480 | |

| 12″ | 300 | 711 | 521 | 451 | 381 | 51 | 16- Φ32 | 550 | |

| 14″ | 350 | 838 | 584 | 514.5 | 413 | 54 | 20- Φ32 | 620 | |

| 16″ | 400 | 864 | 648 | 571.5 | 470 | 58 | 20- Φ35 | 650 | |

| 18″ | 450 | 978 | 711 | 628.7 | 533.4 | 61 | 24- Φ35 | 690 | |

| 20″ | 500 | 1016 | 775 | 685.8 | 584 | 64 | 24- Φ35 | 740 | |

| 24″ | 600 | 1346 | 914.4 | 812.8 | 692 | 70 | 24- Φ41 | 800 | |

| 28″ | 700 | 1499 | 1035 | 939.8 | 800 | 86 | 28- Φ45 | 860 | |

| 30″ | 800 | 1594 | 1092 | 997 | 857 | 92 | 28- Φ48 | 980 | |

| H

H44W-600Lb Y |

2″ | 50 | 292 | 165 | 127 | 92 | 26 | 8- Φ19 | 190 |

| 21/2″ | 65 | 330 | 190.5 | 149.4 | 104.7 | 29 | 8- Φ22 | 210 | |

| 3″ | 80 | 356 | 210 | 168.2 | 127 | 32 | 8- Φ22 | 230 | |

| 4″ | 100 | 432 | 273 | 216 | 157 | 38 | 8- Φ25 | 300 | |

| 5″ | 125 | 508 | 330 | 266.7 | 185.7 | 45 | 8- Φ29 | 310 | |

| 6″ | 150 | 559 | 356 | 292 | 216 | 48 | 12- Φ29 | 370 | |

| 8″ | 200 | 660 | 419 | 349 | 270 | 56 | 12- Φ32 | 450 | |

| 10″ | 250 | 787 | 508 | 432 | 324 | 64 | 16- Φ35 | 500 | |

| 12″ | 300 | 838 | 559 | 489 | 381 | 67 | 20- Φ35 | 570 | |

| 14″ | 350 | 889 | 603 | 527 | 413 | 70 | 20- Φ38 | 640 | |

| 16″ | 400 | 991 | 686 | 603 | 470 | 77 | 20- Φ41 | 670 | |

| 18″ | 450 | 1092 | 743 | 654 | 533.4 | 83 | 20- Φ44 | 710 | |

| 20″ | 500 | 1194 | 855 | 724 | 584 | 89 | 24- Φ44 | 760 | |

| 24″ | 600 | 1397 | 1040 | 838 | 692 | 102 | 24- Φ52 | 830 | |

| H

H44W -900Lb Y |

2″ | 50 | 368 | 216 | 165.1 | 92 | 38.5 | 8- Φ26 | 220 |

| 21/2″ | 65 | 419 | 244 | 190.5 | 104.7 | 41.5 | 8- Φ29 | 250 | |

| 3″ | 80 | 381 | 241 | 190.5 | 127 | 38.5 | 8- Φ26 | 270 | |

| 4″ | 100 | 457 | 292 | 234.9 | 157 | 44.5 | 8- Φ32 | 330 | |

| 5″ | 125 | 559 | 349 | 279.4 | 185.7 | 51 | 8- Φ35 | 350 | |

| 6″ | 150 | 610 | 384 | 317.5 | 216 | 56 | 12- Φ32 | 420 | |

| 8″ | 200 | 737 | 470 | 393.7 | 270 | 63.5 | 12- Φ39 | 490 | |

| 10″ | 250 | 838 | 545 | 469.9 | 324 | 70 | 16- Φ39 | 550 | |

| 12″ | 300 | 965 | 610 | 533.4 | 381 | 79.5 | 20- Φ39 | 630 | |

| 14″ | 350 | 1029 | 640 | 558.8 | 413 | 86 | 20- Φ42 | 680 | |

| 16″ | 400 | 1130 | 705 | 615.9 | 470 | 89 | 20- Φ45 | 720 | |

| 18″ | 450 | 1219 | 785 | 685.8 | 533.4 | 102 | 20- Φ51 | 750 | |

| 20″ | 500 | 1321 | 855 | 749.3 | 584 | 108 | 20- Φ54 | 800 | |

| 24″ | 600 | 1549 | 1040 | 901.7 | 692 | 140 | 20- Φ67 | 880 | |