Ⅰ. Product Introduction

The All Plastic Butterfly Valve is a high-performance fluid control component specifically designed for scenarios requiring excellent corrosion resistance, lightweight properties, and reliable sealing. It adopts an all-plastic structural design (with key metal parts made of corrosion-resistant stainless steel) to avoid the problem of easy rust and corrosion of traditional metal butterfly valves, making it widely applicable to chemical, pharmaceutical, water treatment, food and beverage, electroplating, and other industries. This valve takes the plastic valve body and disc as the core, matching with professional elastic sealing seats, and realizes the on-off and flow regulation of fluid through the rotation of the disc. It has the advantages of simple structure, small volume, light weight, convenient installation and operation, and low maintenance cost. Whether it is for conveying corrosive media such as acids, alkalis, salts, or high-purity media that require no pollution, the All Plastic Butterfly Valve can meet the strict use requirements and provide stable and efficient fluid control solutions.

Ⅱ. Product Features

-

Excellent Corrosion Resistance: The main components such as the valve body and disc are made of high-quality plastic materials such as PPH, RPP, PE, PVDF, CPVC, and UPVC. These materials have strong resistance to most corrosive media (acids, alkalis, salts, organic solvents, etc.), and can maintain stable performance in harsh working environments, effectively extending the service life of the valve.

-

Lightweight and Easy Installation: Compared with traditional metal butterfly valves, the all-plastic structure greatly reduces the weight of the valve, which is convenient for transportation, hoisting, and on-site installation. It can be easily installed in various pipeline systems without the need for complex auxiliary equipment, reducing the installation cost and workload.

-

Reliable Sealing Performance: The valve seat is made of high-quality elastic materials such as FPM (fluorine rubber) and EPDM (ethylene propylene diene monomer rubber), which have good elasticity, wear resistance, and corrosion resistance. It forms a tight seal with the plastic disc, ensuring zero leakage of the valve during use and effectively preventing the loss of media and environmental pollution.

-

Stable Flow Regulation Performance: The optimized disc design and reasonable flow channel structure make the valve have excellent flow regulation characteristics. It can realize stepless regulation of fluid flow within a wide range, and the flow characteristic curve is stable, which can accurately meet the different flow requirements of the system.

-

Strong Adaptability to Media: It is suitable for a variety of media types, including corrosive chemical media, high-purity water, food-grade media, etc. Different plastic materials and sealing materials can be selected according to the specific properties of the conveyed media to ensure the compatibility and safety of the valve.

-

Simple Operation and Maintenance: The valve is equipped with a lightweight and durable handle or worm gear actuator. The operation is simple and labor-saving, and the on-off and regulation can be completed with a small rotation angle. At the same time, the all-plastic structure is not easy to scale and block, and the maintenance work is simple, only requiring regular inspection of the sealing performance and actuator status.

-

Environmentally Friendly and Non-toxic: The selected plastic materials and sealing materials meet the relevant environmental protection and food safety standards, have no toxic and harmful substances, and will not pollute the conveyed media. They are especially suitable for the food and beverage, pharmaceutical, and drinking water treatment industries with high requirements for media purity.

Ⅲ. Technical Data

Butterfly Valve Flow Characteristic Curve

The flow characteristic curve of the All Plastic Butterfly Valve shows the relationship between the relative flow rate (Q/Qmax) and the relative opening degree of the valve. It presents a nearly linear characteristic in the middle opening range (30%-70%), which has excellent flow regulation performance; in the small opening range, the flow rate changes sharply with the opening degree, which is suitable for scenarios requiring precise small-flow control; in the large opening range, the flow rate tends to be stable, which can meet the requirements of large-flow conveying. The specific curve data is as follows (taking the standard caliber valve as an example):

Note: The above data is the typical test result under the condition of standard medium (water) and standard pressure difference. The actual flow characteristic may vary slightly according to the caliber, material, and medium properties of the valve.

Main Parts Material

|

Name (of a thing)

|

Material (that sth is made of)

|

|---|---|

|

Valve Body

|

PPH, RPP, PE, PVDF, CPVC, UPVC

|

|

Tappet

|

1Cr18Ni9Ti

|

|

Valve Disc

|

PPH, RPP, PE, PVDF, CPVC, UPVC

|

|

Valve Seat

|

FPM, EPDM

|

|

Handle (Worm Gear)

|

ABS, Cast Iron, Steel

|

Note: The above materials are standard configurations. According to the special requirements of users (such as higher corrosion resistance, higher temperature resistance), customized material selection can be provided.

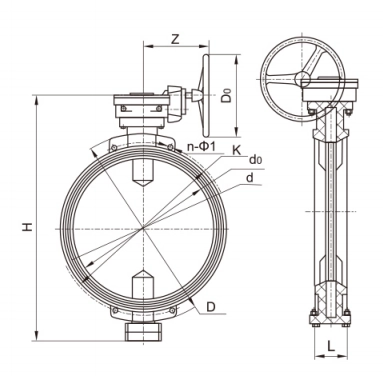

Ⅳ.The main shape and connection size

| German DIN | ||||||||||||

| Nominal diameter | Size (mm) | weights(Kg) | ||||||||||

| DN | NPS | L | D | K | d1 | n-ΦL | H | Z | Do | PE PPH RPP | PVDF | CPVC UPVC |

| 700 | 28 | 165 | 895 | 840 | 680 | 24-Φ30 | 1242 | 306 | 460 | 237 | 306 | 272 |

| 800 | 32 | 190 | 1015 | 950 | 780 | 24-Φ33 | 1327 | 306 | 460 | 267 | 354 | 312 |

| 900 | 36 | 200 | 1115 | 1050 | 870 | 28-Φ33 | 1487 | 306 | 460 | 295 | 405 | 355 |

| 1000 | 40 | 216 | 1230 | 1160 | 970 | 28-Φ36 | 1592 | 306 | 460 | 338 | 457 | 398 |

| 1200 | 48 | 254 | 1455 | 1380 | 1190 | 32-Φ39 | 1872 | 306 | 460 | 400 | 550 | 475 |

| 1400 | 56 | 279 | 1675 | 1590 | 1390 | 36-Φ42 | 2348 | 337 | 460 | 525 | 710 | 606 |

Note: 1) This product can be manufactured in accordance with user requirements, in line with ANSI (American Standard), JIS (Japanese Standard) and other standards for delivery.

2) Selection according to the specific medium temperature, pressure, according to the product performance instructions for reasonable selection.

3)Working temperature:PVDF:-50~+150℃;PPH,RPP:-20~+120℃;PE:-20~+80C;CPVC:0~+90°℃;UPVC:0~+60C.

4) Driving mode: manual, pneumatic, electric, worm gear drive.