Ⅰ. Product Introduction

The HZF-IZ explosion-proof flame arresting breather valve is a key ventilation device specifically installed on petrochemical storage tanks. Its core functions are threefold: first, to prevent the storage tank from being damaged due to overpressure or excessive vacuum inside the tank; second, to block external flames from entering the tank, achieving explosion-proof and flame-arresting effects; third, to effectively reduce the volatilization loss of liquid media inside the tank, ensuring the safety and economy of storage and transportation operations.

The HZF-IZ series breather valve independently developed and designed by our company adopts a scientific and compact structural design. It boasts the advantages of large ventilation capacity and small leakage, which can fully meet the high-standard requirements of petrochemical, chemical, food and other industries for storage tank ventilation. According to the diverse needs of the market, this series of products covers multiple structural forms such as breathing type, single exhaust type and single suction type. Each form can be used independently, and can also be flexibly configured with flame arrester devices and connecting pipes at the exhaust and suction ends to adapt to different application scenarios.

In view of the different characteristics of storage media (such as oil products, chemicals, food, etc.), we select corresponding high-quality materials for production, which fully complies with the process requirements of the storage and transportation system. For occasions with thermal insulation requirements, the product can be customized into a sandwich structure. For special requirements such as special pressure levels and large-diameter specifications, customers only need to provide relevant technical parameters, and our company can carry out personalized design and production to meet the specific needs of customers.

Ⅱ. Product Features

-

Scientific and Compact Structure: The product adopts an optimized structural design, which is small in size and compact in layout, making it easy to install and maintain on various types of storage tanks without occupying too much space.

-

Excellent Ventilation Performance: It has a large ventilation capacity, which can quickly adjust the pressure inside the tank when the pressure inside the tank changes (such as temperature rise leading to pressure increase, or liquid extraction leading to pressure decrease), ensuring the stable operation of the storage tank.

-

Low Leakage Rate: The key sealing parts adopt high-performance materials and advanced sealing technology, which effectively reduces the volatilization loss of the internal medium, saves costs for customers, and also reduces environmental pollution.

-

Strong Adaptability: There are multiple structural forms and material combinations available, which can be customized according to the type of storage medium (oil products, chemicals, food, etc.), pressure requirements, and whether thermal insulation is needed. It is widely applicable to various storage tank scenarios.

-

Reliable Explosion-proof and Flame-arresting Performance: Equipped with a high-performance flame arrester layer, it can firmly block external flames from entering the tank, effectively preventing explosion accidents and ensuring the safety of the storage tank and surrounding environment.

-

High-quality Material Selection: According to different application environments and media characteristics, materials such as cast aluminum alloy, carbon steel, stainless steel (304, 304L, 316, 316L), PP and PVC are selected, which have excellent corrosion resistance, high temperature resistance and mechanical strength, ensuring the long service life of the product.

Ⅲ. Technical Data Summary

3.1 Housing Material and Applicable Media

|

Name

|

Monoblock

|

MinPan

|

Guide Rod

|

Fire Resistance Layer

|

Sealed Seat

|

Applicable Medium

|

|---|---|---|---|---|---|---|

|

Ⅰ

|

Cast aluminium alloy

|

Alufer

|

1CR13

|

304

|

Polytetrafluoroethylene (PTFE)

|

Oil

|

|

Ⅱ

|

Carbon steel

|

304

|

304

|

304

|

Polytetrafluoroethylene (PTFE)

|

Oil products, chemical products

|

|

Ⅲ

|

SS304

|

304

|

304

|

304

|

Polytetrafluoroethylene (PTFE)

|

Chemicals

|

|

Ⅳ

|

SS304L

|

304L

|

304L

|

304L

|

Polytetrafluoroethylene (PTFE)

|

Chemicals

|

|

Ⅴ

|

SS316

|

316

|

316

|

316

|

Polytetrafluoroethylene (PTFE)

|

Chemicals

|

|

Ⅵ

|

SS316L

|

316L

|

316L

|

316L

|

Polytetrafluoroethylene (PTFE)

|

Chemicals

|

|

Ⅶ

|

PP

|

PP

|

PP

|

–

|

PP

|

Chemicals

|

|

Ⅷ

|

PVC

|

PVC

|

PVC

|

–

|

PP

|

Chemicals

|

3.2 Operating Pressure

|

Pressure Rating

|

A

|

B

|

C

|

D

|

|---|---|---|---|---|

|

Exhaust Pressure

|

+355Pa (36mmH₂O)

|

+980Pa (100mmH₂O)

|

+1765Pa (180mmH₂O)

|

Customized by user requirements

|

|

Suction Pressure

|

-295Pa (30mmH₂O)

|

-295Pa (30mmH₂O)

|

-392Pa (40mmH₂O)

|

Customized by user requirements

|

3.3 Aeration Capacity and Leakage Amount

|

Code Name

|

Pressure Rating

|

Nominal Diameter (mm) – Aeration Capacity (m³/h)

|

||||||

|---|---|---|---|---|---|---|---|---|

|

50

|

80

|

100

|

150

|

200

|

250

|

|||

|

A

|

+355Pa

|

25

|

60

|

90

|

190

|

340

|

550

|

|

|

-295Pa

|

20

|

50

|

75

|

160

|

280

|

450

|

||

|

B

|

+980Pa

|

30

|

70

|

100

|

200

|

380

|

600

|

|

|

-295Pa

|

20

|

50

|

75

|

160

|

280

|

450

|

||

|

C

|

+1765Pa

|

40

|

95

|

140

|

280

|

500

|

800

|

|

|

-295Pa

|

20

|

50

|

75

|

160

|

280

|

450

|

||

|

Standard Allowable Leakage (m³/h)

|

≤0.04 (for small specifications) / ≤0.4 (for large specifications)

|

|||||||

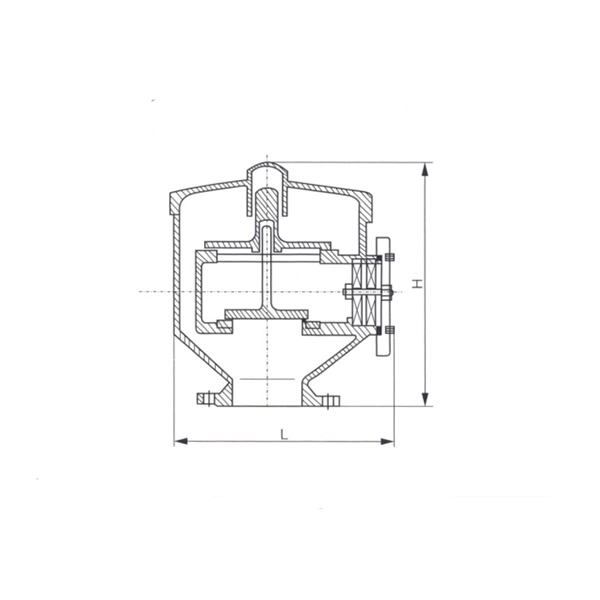

Ⅳ.The main shape and connection size

| DN | L | H |

| 50 | 160 | 255 |

| 80 | 213 | 260 |

| 100 | 265 | 290 |

| 150 | 305 | 330 |

| 200 | 355 | 350 |

| 250 | 420 | 400 |

| 300 | 480 | 51 |