When your engine idles—sitting still at a red light or parked—the Idle Air Control (IAC) Valve quietly keeps everything running smooth. Understanding how this little but vital component works can help you diagnose issues fast and optimize engine performance.

What Is the Idle Air Control (IAC) Valve?

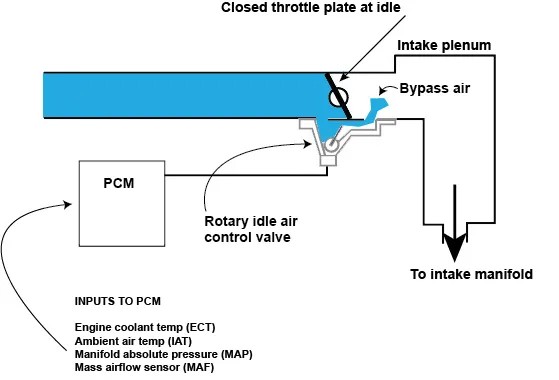

The IAC valve is an electronically controlled component—typically mounted on or near the throttle body—that lets air bypass the throttle plate when the engine is idling. By doing this, it keeps the engine running steadily at idle instead of stalling. This valve uses a solenoid or stepper-motor-driven plunger that adjusts airflow under commands from your vehicle’s Engine Control Unit (ECU).

How the Idle Air Control (IAC) Valve Works

Source: Rickfree

1. Basic Operation: Controlling Airflow at Idle

At idle, the throttle plate is closed, but the engine still needs air to keep running. The IAC valve opens a bypass passage to let air enter the intake manifold, keeping the engine at a steady idle RPM. It achieves this by moving a plunger or rotary mechanism to vary airflow in response to engine needs.

2. Integration with the ECU and Throttle Body

The IAC valve operates under the command of the Engine Control Unit (ECU), which constantly monitors engine conditions. When RPM dips or load increases—say, from turning on the AC—the ECU signals the IAC to open slightly, allowing more air in. When the engine speed is too high, it pulls back the air.

In many cases, the IAC valve is mounted right on the throttle body to simplify this bypass system.

3. Variations in IAC Design Across Vehicles

There are several common IAC designs that vary by vehicle:

-

Stepper Motor (Linear Actuator): Uses a small motor with precise steps to control the plunger position, offering fine airflow adjustment.

-

Duty-Control Solenoid (Rotary or Plunger): Uses pulsed electrical signals (known as duty cycles) to open or close the valve incrementally. Common in many Ford vehicles.

-

On/Off Solenoid Valve: Simply opens or closes, rather than offering variable control.

-

Thermostatic IAC: Uses temperature-sensitive elements—like wax pellets—so the bypass is more open during cold starts and gradually closes as the engine warms.

These systems are tuned to match specific engine control strategies and adapt to different loading conditions.

What Happens When You Unplug the Idle Air Control Valve?

Immediate Effects on Engine Idle Stability and RPM Fluctuations

When you unplug the Idle Air Control (IAC) valve, the Engine Control Unit (ECU) loses its ability to manage airflow at idle. The result? Unpredictable RPM swings. The idle can bounce up and down due to changes in temperature, engine load, or even being in gear, leading to rough engine behavior—not the smooth idle it’s designed to maintain.

Some users report the idle RPM dropping to a base level (often around 600–700 RPM) with little control. In other cases, the engine might surge or hunt, as the ECU struggles to stabilize idle without feedback from the IAC.

Impact on Fuel Efficiency and Engine Warm-Up Time

Unplugging the IAC disrupts the idle control system, which can lead to inefficient combustion. Without regulated airflow, the engine may consume more fuel and take longer to reach optimal operating temperature. The poorly controlled idle can also throw off fuel management, making warm‑up phases less efficient and costing on fuel economy.

Effects on the Air-Fuel Mixture and Engine Strain

An unplugged IAC means the air‑fuel mixture becomes erratic. The ECU isn’t getting correct data to fine‑tune idle airflow, leading to possible lean or rich conditions—either way, putting extra stress on engine components.

In some scenarios, this imbalance can strain the catalytic converter and increase emissions, as the mixture gets out of the ideal range and combustion efficiency drops.

Consequences of Unplugging the IAC Valve on Other Engine Components

1. Potential Damage to the Catalytic Converter from Irregular Exhaust Emissions

Unplugging the Idle Air Control (IAC) valve disrupts the controlled idle airflow, leading to inconsistent air–fuel mixtures. This can result in incomplete combustion and introduce unburnt fuel into the exhaust system. Over time, this unburnt fuel may overheat or degrade the catalytic converter, reducing its effectiveness and accelerating wear.

2. ECU Communication Disruption and Its Impact on Engine Performance

The IAC valve is a critical feedback component for the Engine Control Unit (ECU). When unplugged, the ECU loses a key input it needs to regulate idle speed. This leads to miscommunication, erratic idle, possible check-engine warnings, and overall degraded engine performance.

3. Increased Wear and Tear on Engine Parts Due to Unstable Idle

An unstable or fluctuating idle puts extra stress on multiple engine systems:

-

Components like motor mounts, belts, and pulleys endure constant vibration.

-

Frequent stalls or idle surges increase mechanical wear on the starter, alternator, and transmission linkages.

This strain isn’t harmless—it contributes to premature wear and can lead to more significant failures over time.

Signs and Symptoms Indicating IAC Valve Issues

• Rough Idling and Engine Stalling

When the Idle Air Control (IAC) Valve isn’t regulating airflow properly, you’ll often notice the engine sits unevenly—RPMs bounce or drop unexpectedly. This leads to noticeable shaking or rough idle. In worse cases, especially at stoplights or when starting, the engine can stall entirely.

• Check Engine Warning Light Activation

The Engine Control Unit (ECU) constantly monitors the IAC’s performance. If it detects any fault, it logs a trouble code and switches on the “Check Engine” or MIL (Malfunction Indicator Light).

• Changes in Fuel Consumption and Vehicle Drivability

A failing IAC valve messes with idle airflow and air–fuel mixture, which often translates into poor drivability—hesitation, rough transitions, and even hard starting. Over time, the disrupted idle can also cause your vehicle to consume more fuel than normal.

Risks of Driving with an Unplugged or Faulty Idle Air Control Valve

1. Short-Term vs. Long-Term Risks to Engine Health

-

Short-Term Risks: Driving with a malfunctioning or unplugged IAC valve can lead to engine stalling—especially when idling at traffic lights or during acceleration from a stop—creating immediate safety hazards.

-

Long-Term Risks: More worrisome is the sustained damage. By causing irregular air–fuel mixtures and combustion, a faulty IAC puts uneven stress on engine components over time. This imbalance often leads to increased wear on mechanical systems and potential engine failure down the road.

2. Impact on Emissions and Regulatory Compliance

-

An unplugged or faulty IAC disrupts airflow regulation, resulting in incomplete or inefficient combustion. This elevates levels of harmful exhaust pollutants, placing the catalytic converter under strain and accelerating its wear.

-

Additionally, this malfunction often triggers the “Check Engine” light, leading to automatic failure of emission tests—putting your vehicle at risk of being non-compliant with environmental regulations.

3. Possible Safety Concerns Due to Engine Stalling

-

A nonfunctional IAC weakens your engine’s ability to maintain idle, causing unexpected stalling—particularly during slow maneuvers or idling at intersections. This poses a direct safety risk while on the road.

-

Real-life anecdotes underscore the trouble: drivers report needing to restart frequently and having to avoid stop-and-go traffic entirely. This compounds both safety and practicality risks in everyday driving.

Proper Maintenance and Repair of the IAC Valve

Cleaning and Inspection Tips for the IAC Valve

Routine Cleaning to Prevent Clogging

Over time, carbon buildup and grime can jam the IAC valve’s internal mechanisms and disrupt its function. A regular clean can restore smooth control of idle airflow. The process involves carefully removing the valve from the throttle body, spraying with throttle-body cleaner, gently scrubbing, then drying before reinstalling with fresh gaskets and seals.

DIY Cleaning Made Clear

Step-by-step cleaning guide:

-

Disconnect the vehicle battery and locate the IAC valve.

-

Remove and spray the valve and throttle body mount areas with carbon cleaner.

-

Let them dry, reinstall a new gasket, reconnect everything, and test idle performance.

Deep Cleaning for Stubborn IAC Jams

Community experts suggest a deeper approach—using brake or intake cleaner, soaking the valve in degreaser, lightly lubricating (e.g. with Deep Creep), then reassembling. This can free sticky or soot‑bound IACs effectively.

When to Replace vs. Repair the IAC Valve

Try Cleaning First — If It Moves, Don’t Replace

Many failures are due to dirt-induced jamming. Cleaning is a cost-efficient first step—and may resolve issues entirely if the actuator mechanisms are still functional.

Replace When Mechanically or Electrically Failed

If the valve doesn’t respond even after cleaning—due to a burnt-out motor or damaged electronics—it needs replacement. Jammed actuators sometimes clear by cleaning, but servomotor failures are unrecoverable.

Consider Overall Cost and Practicality

Some users report that replacement (especially with labor) doesn’t justify the cost—suggesting it might be wiser to clean first or shop around for more affordable options.

Professional Diagnostic and Repair Advice

Use Diagnostics After Repair or Replacement

Even after installing a new IAC, idle issues may persist. It’s recommended to scan for trouble codes, check for vacuum leaks, test the throttle position sensor, and clean the throttle body if problems remain.

Watch for Wiring or Idle Surging Issues

Post-replacement idle surges could result from wiring faults or issues with the throttle position sensor—not the IAC itself. Checking connections is key.

Conclusion

Unplugging the Idle Air Control (IAC) valve may seem like a quick fix for idle issues, but it often leads to unstable RPMs, poor fuel efficiency, increased engine strain, and even safety risks from sudden stalling. The IAC plays a crucial role in maintaining idle stability, supporting proper air–fuel balance, and ensuring compliance with emissions standards. Ignoring its function or neglecting timely maintenance can result in long-term engine damage and costly repairs. Whether it’s rough idling, check engine warnings, or drivability concerns, addressing IAC valve issues through proper cleaning, diagnostics, or replacement is essential to keep your engine running reliably and efficiently.