一.Product Introduction

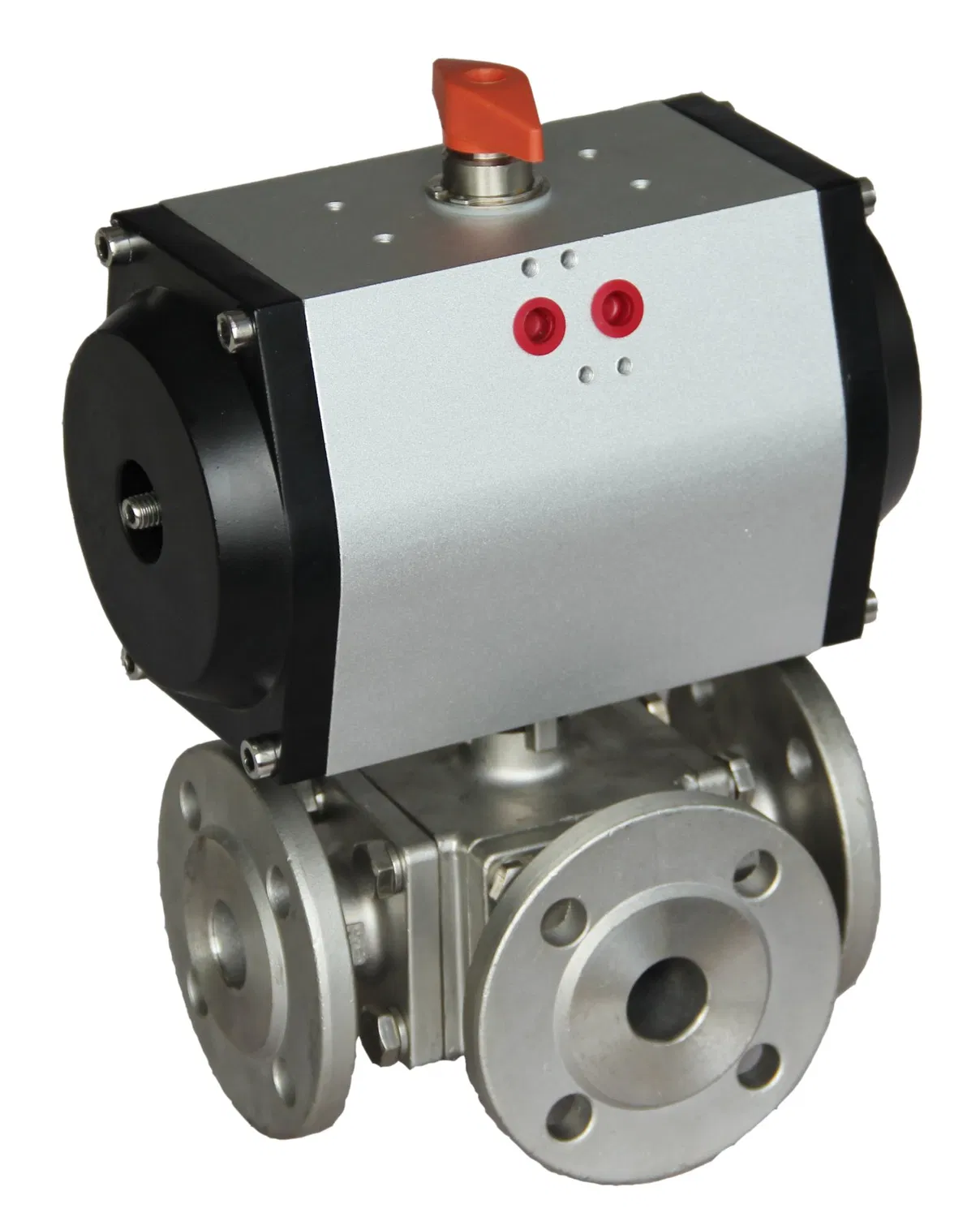

The Piston Pneumatic Actuator Equipped Flanged Ball Valve is a high-performance industrial control valve engineered to meet the rigorous requirements of ANSI, EN, and JIS standards, making it a versatile solution for global industrial applications. Combining a robust piston-type pneumatic actuator with a precision-machined flanged ball valve, this product is designed to deliver reliable, fast-acting flow control across a wide range of media, including liquids, gases, and vapors. It is widely utilized in industries such as oil and gas, petrochemicals, power generation, water treatment, and chemical processing, where efficient shut-off, throttling, or on-off control is critical. The integration of standardized flanged connections ensures seamless compatibility with existing pipeline systems, while the piston actuator provides superior thrust and response speed compared to diaphragm-type actuators, enabling precise operation even under high-pressure and high-temperature conditions. With a focus on durability, safety, and operational efficiency, the GT Series valve is an ideal choice for demanding industrial environments that require consistent performance and long service life.

二.Product Features

- Dual-Standard Compliance: Strictly manufactured in accordance with ANSI, EN, and JIS standards, ensuring global interchangeability and compatibility with international pipeline systems, reducing installation and maintenance costs for cross-border projects.

- High-Thrust Piston Actuator: Equipped with a double-acting or spring-return piston pneumatic actuator, generating strong output torque to handle large-diameter valves and high-pressure differentials. The actuator’s rugged construction minimizes wear and tear, ensuring stable operation over millions of cycles.

- Robust Flanged Ball Valve Design: The flanged end connections (available in Class 150~2500 for ANSI, PN10~PN400 for EN, and 10K~63K for JIS) provide secure, leak-tight sealing, suitable for high-pressure and high-temperature applications. The ball is precision-ground to ensure tight shut-off and minimal flow resistance.

- Superior Sealing Performance: Adopts advanced sealing materials such as PTFE, RPTFE, or metal-to-metal seals, depending on the application requirements. The seals are designed to resist corrosion, erosion, and high temperatures, ensuring zero leakage and extended service life.

- Fast Response and Precise Control: The piston actuator offers quick opening and closing times, typically ranging from 0.5 to 5 seconds (depending on valve size and pressure), making it suitable for automated control systems that require rapid response to process changes. Optional positioners can be installed for proportional control, enhancing control accuracy.

- Corrosion Resistance: The valve body and internal components are available in a variety of materials, including carbon steel, stainless steel (304, 316, 316L), duplex stainless steel, and alloy steel, to accommodate different media and operating environments, providing excellent corrosion resistance and durability.

- Easy Installation and Maintenance: The compact and lightweight design simplifies installation, while the split-body or three-piece body structure allows for easy disassembly and maintenance without removing the valve from the pipeline. The actuator is modular and easy to replace or repair.

- Safety and Reliability: Built-in safety features such as anti-blowout stem design and fire-safe construction (compliant with API 607/ISO 10497) ensure safe operation even in extreme conditions, preventing stem blowout and minimizing fire hazards.

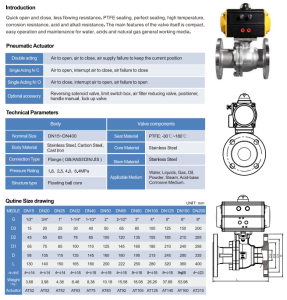

三.Technical Data

| Parameter | Specification |

| Valve Type | Flanged Ball Valve, Full Port or Reduced Port |

| Actuator Type | Piston Pneumatic Actuator (Double-Acting / Spring-Return) |

| Standards Compliance | – Design & Manufacturing: ANSI B16.34, EN 12516, JIS B2002>- Flange Connection: ANSI B16.5, EN 1092-1, JIS B2220>- Face-to-Face Dimension: ANSI B16.10, EN 558-1, JIS B2003: API 607, ISO 10497age Class: ANSI FCI 70-2 Class V (soft seal), Class IV (metal seal) |

| Nominal Diameter (DN) | ANSI: 1/2″ ~ 24″ (NPS 1/2 ~ NPS 24)/JIS: DN15 ~ DN600 |

| Nominal Pressure (PN) | ANSI: Class 150, 300, 600, 900, 1500, 2500: PN10, PN16, PN25, PN40, PN63, PN100, PN160, PN250, PN400JIS: 10K, 20K, 30K, 40K, 63K |

| Operating Temperature Range | – Soft Seal: -40℃ ~ +200℃ (PTFE), -20℃ ~ +260℃ (RPTFE) Seal: -29℃ ~ +425℃ (carbon steel), -196℃ ~ +550℃ (stainless steel) |

| Media Compatibility | Water, Oil, Gas, Steam, Chemicals, Slurries, etc. (depending on material selection) |

| Body Material | Carbon Steel (A105, WCB), Stainless Steel (A182 F304, F316, F316L), Duplex Stainless Steel (F51, F53), Alloy Steel (F11, F22) |

| Ball/Stem Material | Ball: Stainless Steel (304, 316, 316L), Hardened Stainless Steel (Stellite Coated)em: Stainless Steel (304, 316), Alloy Steel |

| Seat Material | Soft Seal: PTFE, RPTFE, Viton, EPDMMetal Seal: Stellite, Hastelloy, Inconel |

| Actuator Output Torque | 5 N·m ~ 5000 N·m (depending on actuator size and supply pressure) |

| Supply Pressure | 0.4 ~ 1.0 MPa (compressed air) |

| Response Time | 0.5 ~ 5 seconds (double-acting), 1.0 ~ 8 seconds (spring-return) |

| Positioner Option | Pneumatic Positioner, Electro-Pneumatic Positioner (4-20mA signal) |

| Accessories | Limit Switch, Solenoid Valve, Filter Regulator, Speed Controller, Manual Override |

| Protection Class | IP65, IP67 (actuator) |

| Ambient Temperature | -20℃ ~ +80℃ (standard), -40℃ ~ +120℃ (optional) |

四.The main shape and connection size