Ⅰ.Product Introduction

A pneumatic actuated ball valve is a type of quarter-turn valve that combines a ball valve core with a pneumatic actuator. It uses compressed air as the power source to drive the actuator, which in turn rotates the ball valve’s spherical core (90° on/off) to control the on/off or throttling of fluid media. Widely applied in petroleum, chemical, water treatment, food and beverage, and pharmaceutical industries, it is favored for its fast response, stable operation, and suitability for automatic control systems. The valve’s core features a hollow or solid spherical structure—when the hollow part aligns with the valve port, media flows; when rotated 90°, the solid part blocks the port to cut off flow.

Ⅱ.Product Features

- Fast Response & High Efficiency: Pneumatic actuation enables rapid 90° rotation (typical response time: 0.5–5s), suitable for scenarios requiring quick on/off switching, outperforming manual or electric valves in speed.

- Stable & Reliable Operation: Compressed air drive avoids electrical faults (e.g., short circuits) and has no electromagnetic interference, ensuring stable performance in harsh environments (high temperature, humidity, flammability).

- Excellent Sealing Performance: Adopts precision-ground spherical core and elastic sealing rings (PTFE, EPDM, FKM), achieving bubble-tight sealing to prevent media leakage, even for corrosive or viscous media.

- Corrosion & Wear Resistance: Valve body materials include stainless steel (304/316L), carbon steel, and PVC; actuator parts use anti-corrosion coatings, adapting to corrosive media (acids, alkalis) and extending service life.

- Easy Automation Integration: Supports connection with solenoid valves, positioners, and sensors, enabling remote control and real-time monitoring of valve status, matching industrial automation systems.

- Low Maintenance: Simple structure with fewer moving parts; the ball valve’s smooth surface reduces media deposition, lowering cleaning and maintenance frequency.

Ⅲ.Technical data

| Item | Typical Specifications |

|---|---|

| Valve Size | DN10–DN300 (1/4″–12″) |

| Nominal Pressure | PN1.6MPa, PN2.5MPa, PN4.0MPa, ANSI Class 150, Class 300 |

| Temperature Range | -40°C–200°C (depends on sealing material; PTFE: -20°C–180°C; EPDM: -40°C–120°C) |

| Media Compatibility | Water, oil, gas, acid, alkali, food-grade fluids, etc. (matches body/sealing material) |

| Pneumatic Actuator | Double-acting (air drive for on/off) / Single-acting (air drive open, spring return close; or vice versa) |

| Operating Pressure (Air) | 0.4–0.8MPa (compressed air source) |

| Valve Body Material | Stainless Steel (304/316L), Carbon Steel (WCB), PVC, PPH |

| Ball Material | Stainless Steel (304/316L), Carbon Steel |

| Sealing Material | PTFE, EPDM, FKM (Viton), NBR |

| Connection Type | Flanged (PN/ANSI), Threaded (NPT/BSP), Welded (Socket Weld/Butt Weld) |

| Action Type | 90° Quarter-Turn (On/Off), Throttling (for V-port ball valve) |

| Position Indicator | Mechanical pointer, Magnetic reed switch, Limit switch |

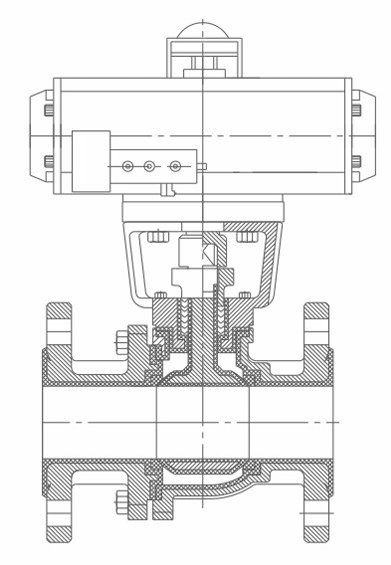

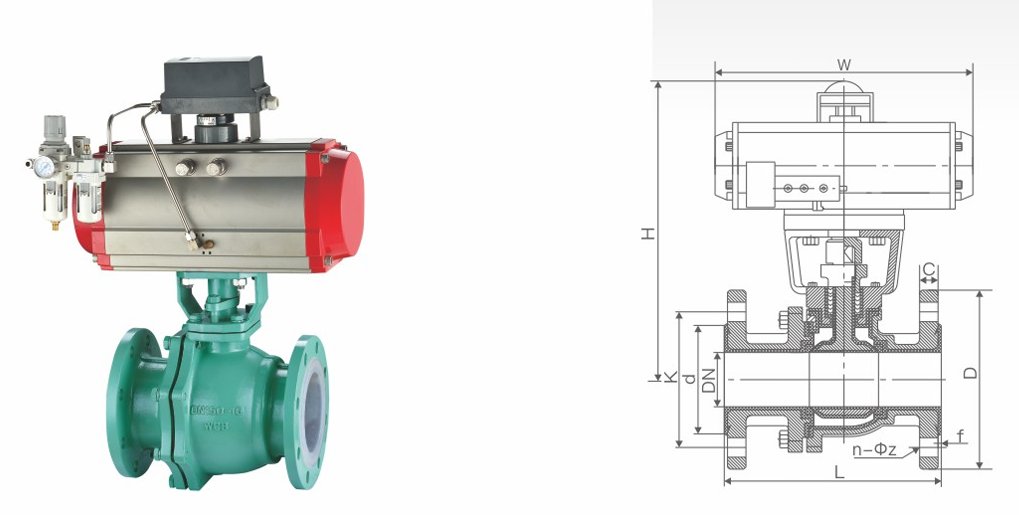

Ⅳ.The main shape and connection size

| DN | Kv | Pneumatic (Double) | Pneumatic (Single) | Electric Torque (Nm) |

|---|---|---|---|---|

| DN15 | 19 | AT52 | AT63S | 5 |

| DN20 | 38 | AT52 | AT63S | 10 |

| DN25 | 72 | AT63S | AT75S | 16 |

| DN32 | 110 | AT63S | AT83S | 20 |

| DN40 | 170 | AT75 | AT92S | 40 |

| DN50 | 270 | AT83 | AT105S | 50 |

| DN65 | 450 | AT92 | AT125S | 60 |

| DN80 | 510 | AT105 | AT140S | 100 |

| DN100 | 940 | AT125 | AT160S | 160 |

| DN125 | 1400 | AT140 | AT160S | 200 |

| DN150 | 2200 | AT160 | AT190S | 100 |

| DN200 | 3500 | AT210 | AT240S | 160 |

| DN250 | 5650 | AT270 | AT300S | 200 |

| DN300 | 8000 | AT300 | AT350S | 200 |

| DN | NPS | L | D | K | d | C | f | n-Φz | W | H |

| 15 | 1/2″ | 140 | 95 | 65 | 45 | 16 | 2 | 4-Φ14 | 145 | 205 |

| 20 | 3/4″ | 140 | 105 | 75 | 55 | 18 | 2 | 4-Φ14 | 145 | 208 |

| 25 | 1″ | 150 | 115 | 85 | 65 | 18 | 2 | 4-Φ14 | 169 | 210 |

| 32 | 1 1/4″ | 165 | 140 | 100 | 75 | 18 | 2 | 4-Φ18 | 169 | 232 |

| 40 | 1 1/2″ | 180 | 150 | 110 | 85 | 18 | 3 | 4-Φ18 | 201 | 274 |

| 50 | 2″ | 200 | 165 | 125 | 100 | 18 | 3 | 4-Φ18 | 209 | 287 |

| 65 | 2 1/2″ | 220 | 185 | 145 | 120 | 18 | 3 | 8-Φ18 | 242 | 327 |

| 80 | 3″ | 250 | 200 | 160 | 135 | 20 | 3 | 8-Φ18 | 275 | 363 |

| 100 | 4″ | 280 | 220 | 180 | 155 | 20 | 3 | 8-Φ18 | 332 | 398 |

| 125 | 5″ | 320 | 250 | 210 | 185 | 22 | 3 | 8-Φ18 | 385 | 432 |

| 150 | 6″ | 360 | 285 | 240 | 210 | 22 | 3 | 8-Φ22 | 450 | 475 |

| 200 | 8″ | 400 | 340 | 295 | 265 | 24 | 3 | 8-Φ22 | 562 | 615 |

| 250 | 10″ | 450 | 395 | 350 | 320 | 26 | 3 | 12-Φ22 | 722 | 740 |

| 300 | 12″ | 610 | 445 | 400 | 370 | 26 | 4 | 12-Φ22 | 830 | 885 |