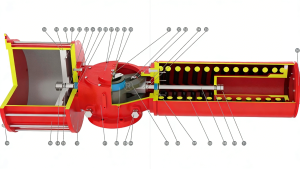

I. Product Introduction

A single-acting pneumatic actuator is a vital component in industrial automation, designed to convert compressed air energy into mechanical motion (rotary or linear) for controlling valves, dampers, and other process equipment. As a core variant of pneumatic actuation systems, the single-acting pneumatic actuator serves as the “muscle” behind pneumatic valve systems, enabling automated opening, closing, or modulation of valves in industries such as oil and gas, chemical processing, water treatment, pharmaceuticals, and manufacturing. By leveraging compressed air as the driving force and integrating a spring-return mechanism as its signature feature, the single-acting pneumatic actuator delivers reliable, fast-acting performance, making it indispensable for precise process control, remote operation, and safety-critical applications. Its ability to operate without electrical power also lends intrinsic safety in explosive or flammable environments, further expanding the utility of the single-acting pneumatic actuator across diverse industrial landscapes.

II. Product Features

1. Pneumatic-Driven Advantages of Single-Acting Pneumatic Actuators

- Fast Response Times: A single-acting pneumatic actuator actuates valves or equipment in milliseconds to seconds, enabling rapid process adjustments and emergency shutdowns in critical scenarios.

- High Power-to-Weight Ratio: A single-acting pneumatic actuator delivers significant torque or force relative to its compact size, making it suitable for large valves or high-pressure systems where space is limited.

2. Safety & Reliability of Single-Acting Pneumatic Actuators

- Intrinsic Safety: A single-acting pneumatic actuator operates without electrical components, eliminating spark risks in hazardous (explosive/flammable) environments such as chemical plants and oil refineries.

- Fail-Safe Mechanisms: As the defining characteristic of a single-acting pneumatic actuator, its built-in spring-return mechanism ensures the actuator reverts to a predefined position (open/close) during air supply failure, effectively safeguarding industrial processes and preventing operational accidents.

3. Durability & Low Maintenance of Single-Acting Pneumatic Actuators

- Robust Construction: A single-acting pneumatic actuator is built with high-quality materials like anodized aluminum, stainless steel, or reinforced polymers to resist corrosion, wear, and harsh chemical corrosion, adapting to severe working conditions.

- Minimal Moving Parts: A single-acting pneumatic actuator features a simplified mechanical structure with fewer components, which reduces wear and tear, leading to extended service life and significantly reduced maintenance costs for users.

4. Versatility & Integration of Single-Acting Pneumatic Actuators

- Valve Compatibility: A single-acting pneumatic actuator works seamlessly with quarter-turn valves (ball, butterfly, plug) and can be adapted to linear valves with the addition of auxiliary accessories, meeting diverse valve control requirements.

- Control System Integration: A single-acting pneumatic actuator can be seamlessly connected with solenoid valves, positioners, and sensors, enabling automated or remote control via pneumatic or digital systems to realize intelligent process regulation.

5. Precise Control Options of Single-Acting Pneumatic Actuators

- Modulating Capability: A single-acting pneumatic actuator is available in on/off (two-position) or proportional (modulating) designs, supporting precise flow or position control for different industrial process needs.

- Positioning Accuracy: When paired with a dedicated positioner, a single-acting pneumatic actuator achieves precise valve positioning (e.g., ±1% of stroke), ensuring stable and accurate process parameter control.

III. Technical Data

1. Torque & Force Output

- Rotary Single-Acting Pneumatic Actuators (Quarter-Turn): Torque ranges from 5 Nm to 5,000 Nm (e.g., a compact single-acting pneumatic actuator like Festo DFPD-20 delivers 20.1 Nm of torque).

- Linear Single-Acting Pneumatic Actuators: Force ranges from 100 N to 100,000 N, depending on piston size and air pressure supplied to the single-acting pneumatic actuator.

2. Air Supply & Pressure

- Operating Pressure: 2–8 bar (30–120 psi) for standard single-acting pneumatic actuators; some high-performance single-acting pneumatic actuator units support up to 10 bar (145 psi) for heavy-duty applications.

- Air Consumption: Varies by the size of the single-acting pneumatic actuator (e.g., a small rotary single-acting pneumatic actuator may consume 0.5–2 liters per cycle).

3. Motion & Speed

- Swivel Angle (Rotary Single-Acting Pneumatic Actuators): 90° (standard for quarter-turn valves), with adjustable angles (e.g., 85–95°) available in customized single-acting pneumatic actuator models.

- Actuation Speed: 0.5–10 seconds per 90° stroke, which varies by the size of the single-acting pneumatic actuator, input air pressure, and actual load.

4. Physical & Environmental

- Temperature Range: -20°C to +80°C for standard single-acting pneumatic actuators; extended temperature ranges (-40°C to +120°C) are available for single-acting pneumatic actuators used in extreme working conditions.

- Material: The housing of a single-acting pneumatic actuator is made of durable materials including anodized aluminum, stainless steel (304/316), or engineered plastics, ensuring corrosion resistance and structural strength.

- Protection Class: IP65/IP67 for most single-acting pneumatic actuators, providing excellent dust and water resistance for outdoor or harsh industrial use scenarios.

5. Mounting & Connection

- Mounting Standard: A single-acting pneumatic actuator is compliant with ISO 5211 (flange hole patterns like F03, F05, F10), ensuring universal compatibility with various industrial valves.

- Pneumatic Connection: G1/8, G1/4, G3/8, or G1/2 (threaded) for standard single-acting pneumatic actuators; some specialized single-acting pneumatic actuator models offer quick-connect or flanged connection options for easy installation.

6. Cycle Life & Reliability

- Cycle Life: A single-acting pneumatic actuator can achieve up to 100,000 cycles or more under normal operating conditions, ensuring long-term stable operation.

- Mean Time Between Failures (MTBF): 50,000–100,000 hours for a single-acting pneumatic actuator, depending on regular maintenance and the operating environment.

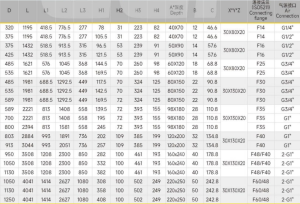

四.The main shape and connection size