When working with valve and pipe fittings, understanding different thread standards is crucial to ensure compatibility and prevent leakage in piping systems. Among the various standards available, NPT, BSPP, and BSPT are some of the most common. Each has unique characteristics, applications, and purposes that make it suitable for specific environments. This article will explain the differences between these thread types, helping you make informed decisions about which is best for your needs.

Understanding the Basics: NPT, BSPP, and BSPT

NPT (National Pipe Tapered), BSPP (British Standard Pipe Parallel), and BSPT (British Standard Pipe Tapered) define thread standards for various plumbing, hydraulic, and pneumatic applications. While their differences may seem subtle, they significantly impact the compatibility and safety of piping systems.

NPT (National Pipe Tapered)

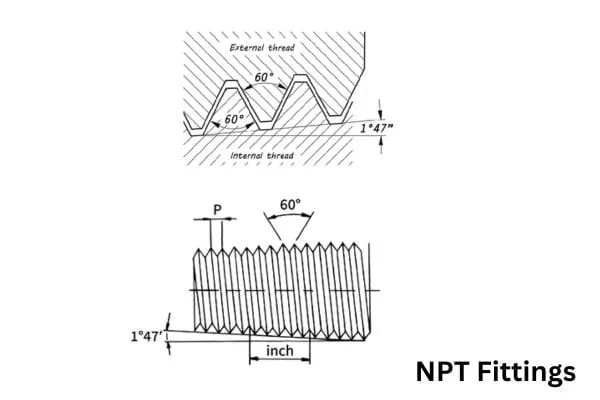

North America widely uses NPT threads. They have a 60° thread angle with flattened peaks and valleys. These threads taper, with their diameter decreasing along the thread length. This tapering enables a pressure-tight seal when used with a sealant, such as PTFE tape. However, NPT threads do not provide a reliable seal without a sealing compound, as leakage can occur through the thread helix. Therefore, NPT threads are suitable for general fluid transport but not for critical pressure-tight applications without additional sealing.

NPT Thread Chart

| Nominal Pipe Size (NPS) | Threads per Inch (TPI) | Outside Diameter (OD) (inches) | Pitch Diameter (inches) | Hand Tight Engagement (L1) (inches) |

|---|---|---|---|---|

| 1/8″ | 27 | 0.405 | 0.363 | 0.260 |

| 1/4″ | 18 | 0.540 | 0.495 | 0.400 |

| 3/8″ | 18 | 0.675 | 0.628 | 0.400 |

| 1/2″ | 14 | 0.840 | 0.758 | 0.533 |

| 3/4″ | 14 | 1.050 | 0.982 | 0.533 |

| 1″ | 11-1/2 | 1.315 | 1.200 | 0.680 |

| 1-1/4″ | 11-1/2 | 1.660 | 1.546 | 0.680 |

| 1-1/2″ | 11-1/2 | 1.900 | 1.779 | 0.680 |

| 2″ | 11-1/2 | 2.375 | 2.246 | 0.750 |

Note:

- Threads per Inch (TPI): The number of threads in an inch of the pipe.

- Outside Diameter (OD): The nominal outside diameter of the pipe.

- Pitch Diameter: The average of the major and minor diameters of the thread.

- Hand Tight Engagement (L1): The length of thread engagement when hand-tightened.

These charts help determine the correct NPT, BSPP, or BSPT size for your application, ensuring compatibility and preventing potential issues related to mismatched fittings.

BSPP (British Standard Pipe Parallel)

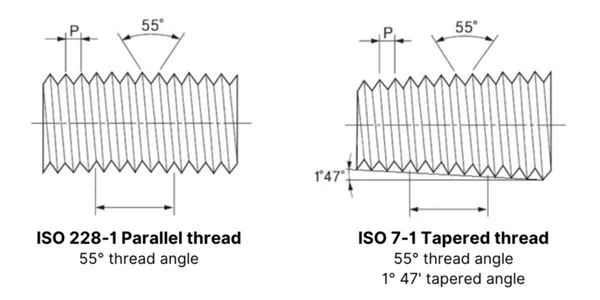

BSPP threads are parallel, meaning the thread diameter is constant. They have a 55° thread angle and rely on an external sealing component, such as an O-ring or gasket, to achieve a fluid-tight connection. This external sealing reduces stress on the threads, allowing for repeated assembly and disassembly. Hydraulic systems and pneumatics commonly use BSPP threads for reliable, reusable connections.

BSPP Thread Chart

| Nominal Pipe Size (NPS) (inches) | Threads per Inch (TPI) | Outside Diameter (OD) (inches) | Pitch Diameter (inches) | Length of Engagement (L1) (inches) |

| 1/8 | 28 | 0.383 | 0.347 | 0.260 |

| 1/4 | 19 | 0.518 | 0.464 | 0.375 |

| 3/8 | 19 | 0.656 | 0.600 | 0.375 |

| 1/2 | 14 | 0.825 | 0.758 | 0.472 |

| 3/4 | 14 | 1.041 | 0.974 | 0.472 |

| 1 | 11 | 1.309 | 1.225 | 0.518 |

| 1-1/4 | 11 | 1.650 | 1.563 | 0.518 |

| 1-1/2 | 11 | 1.882 | 1.794 | 0.518 |

| 2 | 11 | 2.347 | 2.257 | 0.580 |

BSPT (British Standard Pipe Tapered)

BSPT threads taper like NPT threads, but they have a 55° thread angle and rounded thread profiles. This difference makes BSPT threads incompatible with NPT threads. BSPT threads achieve a seal through metal-to-metal contact as the threads are tightened, typically eliminating the need for additional sealing elements. Plumbing applications requiring high pressure and leak-proof connections prefer BSPT threads.

BSPT Thread Chart

| Nominal Pipe Size (NPS) (inches) | Threads per Inch (TPI) | Outside Diameter (OD) (inches) | Pitch Diameter (inches) | Hand Tight Engagement (L1) (inches) |

| 1/8 | 28 | 0.383 | 0.347 | 0.260 |

| 1/4 | 19 | 0.518 | 0.464 | 0.330 |

| 3/8 | 19 | 0.656 | 0.600 | 0.330 |

| 1/2 | 14 | 0.825 | 0.758 | 0.400 |

| 3/4 | 14 | 1.041 | 0.974 | 0.400 |

| 1 | 11 | 1.309 | 1.225 | 0.460 |

| 1-1/4 | 11 | 1.650 | 1.563 | 0.460 |

| 1-1/2 | 11 | 1.882 | 1.794 | 0.460 |

| 2 | 11 | 2.347 | 2.257 | 0.520 |

Key Differences Between BSPP, BSPT, and NPT

Thread Geometry and Profile

BSPP (British Standard Parallel Pipe), BSPT (British Standard Pipe Tapered), and NPT (National Pipe Thread) threads each have distinct thread profiles and geometries. BSPP threads are parallel, meaning they maintain a consistent diameter, which allows for easy assembly and disassembly without causing excessive wear on the threads. In contrast, both BSPT and NPT are tapered threads, which means their diameter narrows toward the tip. The taper in these threads enhances their ability to form tight seals under pressure. However, while BSPT threads have a 55-degree thread angle with rounded peaks and valleys, NPT threads feature a 60-degree angle with flattened peaks, influencing how well they interlock and seal when tightened.

Thread Angle Comparisons

The thread angles of BSPT and NPT threads differ significantly. BSPT threads use a 55-degree angle, resulting in rounded peaks and valleys that contribute to their sealing capabilities. This design is typically used in applications where a strong seal is necessary but not reliant solely on thread contact. On the other hand, NPT threads have a 60-degree angle with flat peaks and valleys, providing a slightly more aggressive seal when tightened. This difference in angles is crucial because it influences how the threads fit together, particularly in high-pressure environments. As a result, BSPT and NPT threads are not compatible with one another, requiring different sealing methods like thread sealants or PTFE tape to ensure leak-proof connections.

Sealing Mechanisms and Applications

How BSPP, BSPT, and NPT Seal

The sealing mechanisms of BSPP, BSPT, and NPT threads differ significantly due to their design and the pressure environments they are intended to support.

- BSPP threads are parallel and rely on an additional sealing element, such as an O-ring or a bonded washer, to create a tight seal. The seal is formed when the male fitting is tightened against the shoulder of the female fitting. This design is most commonly used in low to medium-pressure systems, particularly in industries like automotive and fluid systems where ease of disassembly is important. No thread sealant is required, but a copper crush washer or similar gasket can be used for improved sealing.

- BSPT threads use a tapered design, meaning the male and female threads converge as they are tightened. The sealing occurs when the threads are compressed against each other, creating a metal-to-metal seal. BSPT threads are particularly well-suited for high-pressure applications due to this robust seal. Thread sealants are often required to help achieve a leak-proof connection, and they should be applied carefully to avoid excessive buildup that can lead to leaks.

- NPT threads, also tapered, rely on the principle of “out-of-roundness” for sealing. The male NPT fitting slightly deforms the female fitting as the threads engage, and the pressure from this deformation creates a seal. NPT threads are widely used in high-pressure systems, especially in the U.S. and Canada, and thread sealants like PTFE tape or paste are commonly applied to enhance the seal. However, excessive use of sealants can lead to leakage, so it is recommended to apply just a small amount.

Recommended Sealants for Each Thread Type

- BSPP: Because BSPP threads rely on the compression of a gasket or O-ring rather than thread deformation, no thread sealant is generally required. However, if additional sealing is needed or if the application involves higher pressures or harsh chemicals, a suitable gasket material (e.g., copper or elastomeric washers) can enhance the seal.

- BSPT: BSPT threads generally require a thread sealant to ensure a leak-free connection. Thread sealing compounds such as PTFE-based paste or tape are ideal, as they fill any small gaps in the threads and help prevent leaks under pressure. It is important to apply these sealants conservatively to avoid over-tightening, which could damage the threads.

- NPT: NPT threads also benefit from the use of thread sealants like PTFE tape or liquid thread sealants. These sealants help to ensure a strong, leak-resistant seal by filling the microscopic gaps in the threads. As with BSPT threads, care should be taken not to overapply the sealant, as excess material can result in leaks or damage during installation.

Compatibility Between BSPP, BSPT, and NPT

The compatibility of BSPP, BSPT, and NPT threads is crucial in ensuring proper sealing and functional connections in various piping systems. These thread types, although often used interchangeably in different regions and industries, are not directly compatible with one another due to key differences in their design and structure.

Interchangeability of Threads

When comparing NPT (National Pipe Tapered), BSPT (British Standard Pipe Tapered), and BSPP (British Standard Pipe Parallel) threads, their fundamental differences make direct interchangeability impractical. Each of these threads has distinct characteristics, particularly in their thread angle and profile.

- NPT threads are tapered with a 60-degree angle, designed to seal by the interference between the male and female threads. The taper ensures that the thread seal tightens as the parts are screwed together. This feature provides a robust seal but is incompatible with BSPP or BSPT threads, which have different thread profiles and sealing methods.

- BSPT threads, like NPT, are tapered, but they use a 55-degree thread angle, which differs from NPT’s 60-degree angle. This slight variation in the thread angle prevents the threads from meshing properly with NPT fittings.

- BSPP threads, in contrast, are parallel and have a 55-degree thread angle, which makes them incompatible with both NPT and BSPT threads. While BSPP threads can form a tight seal with the help of a sealing compound, their design is not suitable for direct engagement with tapered NPT or BSPT threads.

Because of these differences, adapters are commonly used to connect BSP and NPT threaded fittings. These adapters compensate for the dimensional and angular discrepancies, but it is crucial to use the correct type to avoid leaks and mechanical failures.

Fitting Connections and Adaptors

Given the structural and angular differences between BSPP, BSPT, and NPT threads, connecting these threads without the proper adapter can result in improper seals or mechanical issues. Adapters are available to facilitate the connection between these different thread types, allowing for flexible and reliable connections in mixed-thread environments.

NPT-to-BSPP-adapters

-

NPT to BSPP/BSPT adapters: These are designed to bridge the gap between the tapered NPT threads and the parallel BSPP or tapered BSPT threads. These fittings allow for a secure connection, although the sealing mechanism may rely on Teflon tape or a thread sealant due to the differences in thread profile.

- BSPP to NPT/BSPT adapters: These adapters work in the opposite direction, connecting the parallel BSPP threads to tapered NPT or BSPT fittings. The sealing compound is also necessary for these connections, as BSPP does not inherently create a tight seal without additional assistance.

Advantages and Limitations of NPT, BSPP, and BSPT Threads

| Thread Type | Advantages | Limitations |

| NPT Threads | – Secure seal due to 60-degree taper, ideal for high-pressure applications.

– Widely available in a range of sizes and materials, especially in North America. – Versatile, suitable for various applications across industries. |

– Potential for leaks if not properly sealed with PTFE tape or sealant.

– Threads may deform over time if over-tightened, compromising the seal. – Not directly compatible with BSP threads (BSPP/BSPT), requiring adapters for international applications. |

| BSPP Threads | – Simple design for easy installation and removal, ideal for low-pressure systems.

– Common in Europe and other regions, ideal for water, air conditioning, and instrumentation systems. – Adaptable to a wide range of industries. |

– Limited to low-pressure applications, as thread engagement alone may not provide adequate sealing under higher pressures.

– Risk of leakage in high-pressure systems due to reliance on thread engagement only. – Compatibility issues with NPT threads; adapters required for proper connection. |

| BSPT Threads | – Superior sealing with a tapered design, ideal for moderate to high-pressure applications.

– Rounded peaks reduce friction, leading to durability and longer-lasting connections. – Ideal for demanding industries (oil, gas, hydraulics) due to high-pressure handling capability. |

– May require additional sealants (e.g., PTFE tape) for optimal performance, especially in high-pressure settings.

– Requires careful assembly and tightening for a secure seal. – Compatibility challenges with BSPP threads; adapters may be necessary for integration, increasing complexity. |